K-WANG

EMERSON 1C31233G04 - Industrial Control Module for Advanced Automation Systems

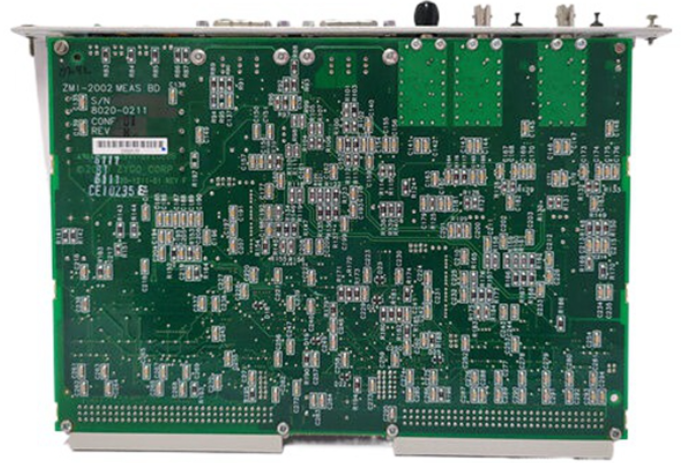

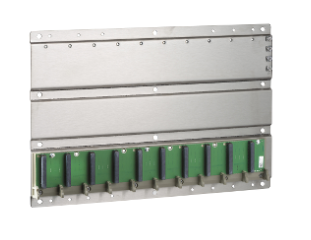

The EMERSON 1C31233G04 is a high-performance automation component specifically engineered to meet the rigorous demands of the power industry, petrochemical plants, and general automation environments. Designed with precision and durability in mind, this model delivers exceptional input/output capacity and reliable performance metrics essential for critical industrial applications. Its robust construction ensures long-term operational stability even under harsh industrial conditions, making the 1C31233G04 an indispensable asset for complex control systems.

At the core of the EMERSON 1C31233G04’s technical features is its advanced signal processing capability, which allows seamless integration with a wide range of sensors and control devices. The unit supports high-density I/O configurations, enabling it to handle numerous analog and digital signals simultaneously without compromising speed or accuracy. This capability is particularly valuable in power generation scenarios where precise monitoring and rapid response are mandatory. Additionally, its built-in redundancy options and fault-tolerant design guarantee uninterrupted operations, minimizing downtime and maintenance costs.

Durability is another hallmark of the EMERSON 1C31233G04. The device is constructed using industrial-grade materials and designed to withstand extreme temperatures, vibration, and electromagnetic interference commonly encountered in petrochemical and power plant environments. Its conformal coating and rugged connectors further protect the system from dust and moisture ingress, ensuring consistent performance in challenging conditions. Moreover, the 1C31233G04 complies with stringent industry standards, underscoring its suitability for mission-critical automation tasks.

The 1C31233G04 excels in real-world applications such as turbine control in power plants, process automation in petrochemical refineries, and integrated control systems for general manufacturing automation. Its rapid data acquisition and processing capabilities allow operators to maintain precise control over complex processes, improving overall efficiency and safety. For example, in a power generation facility, the 1C31233G04 can interface with sensors like the EMERSON PR6424/000-130 CON021 Eddy Current Sensor to monitor turbine shaft vibration and temperature, providing vital feedback to prevent mechanical failures. Similarly, in petrochemical applications, it can coordinate with devices such as the EMERSON Ovation 1X00884H01 Compact Controller to optimize process parameters and ensure regulatory compliance.

When compared to other EMERSON automation products, the 1C31233G04 stands out due to its balanced combination of input/output density, ruggedness, and compatibility with existing control architectures. While models like the EMERSON KJ2002X1-CA1 12P1509X102 Controller Module specialize in control logic execution and the EMERSON MMS6110 focuses on monitoring functions, the 1C31233G04 serves as a versatile interface unit that bridges these capabilities efficiently. Its performance metrics surpass those of the EMERSON 5X00001H15 and EMERSON 5X00082H12, which are often limited in I/O scalability or environmental resistance. Additionally, the 1C31233G04 offers enhanced diagnostic features compared to the EMERSON PR6426/010-040 CON021 Eddy Current Sensor, allowing proactive maintenance and system optimization.

Alongside the EMERSON 1C31233G04, complementary models such as the EMERSON PR6423/002-030 and EMERSON PR6423/018-010 CON021 Eddy Current Sensors provide precise condition monitoring, while the EMERSON Ovation 5A26458G05 and EMERSON VE4002 KJ3007X1-EA1 12P2413X032 Terminal Block facilitate robust control system integration. For power supply stability, the EMERSON UBI3KVA110 ensures uninterrupted power to critical components, including the 1C31233G04. Furthermore, the EMERSON 7380A36G01 PCB Circuit Board and EMERSON DA7281440 support auxiliary control and communication functions within complex automation setups.

The application of the EMERSON 1C31233G04 in power industry, petrochemical, and general automation settings is a testament to its reliability and adaptability. Its compatibility with a broad ecosystem of EMERSON automation products allows for scalable and future-proof system designs. Whether deployed in a high-demand turbine monitoring system or a petrochemical process control network, the 1C31233G04 delivers consistent, precise performance that meets the stringent requirements of modern industrial automation.

In summary, the EMERSON 1C31233G04 is a premium automation solution combining superior input/output capacity, rugged durability, and advanced processing capabilities. When integrated with devices like the EMERSON PR6424/010-010-CN CON021 Eddy Current Sensor and the EMERSON DeltaV VE3007 KJ2003X1-BA2 controller, it forms the backbone of efficient and reliable control systems across multiple industrial sectors. For engineers and system integrators seeking dependable performance in challenging environments, the 1

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|