K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Manufacturers

ABB

Model(s)

ABB Advant Controller 31

Additional Information

We offer a Classic Automation verified replacement battery for this unit. See part number CA-07LE90.

Estimated Shipping Size

Dimensions: 9.5" x 6.0" x 3.5"

(24.1 cm x 15.2 cm x 8.9 cm)

Weight: 1 lbs 14.5 oz (0.9kg )

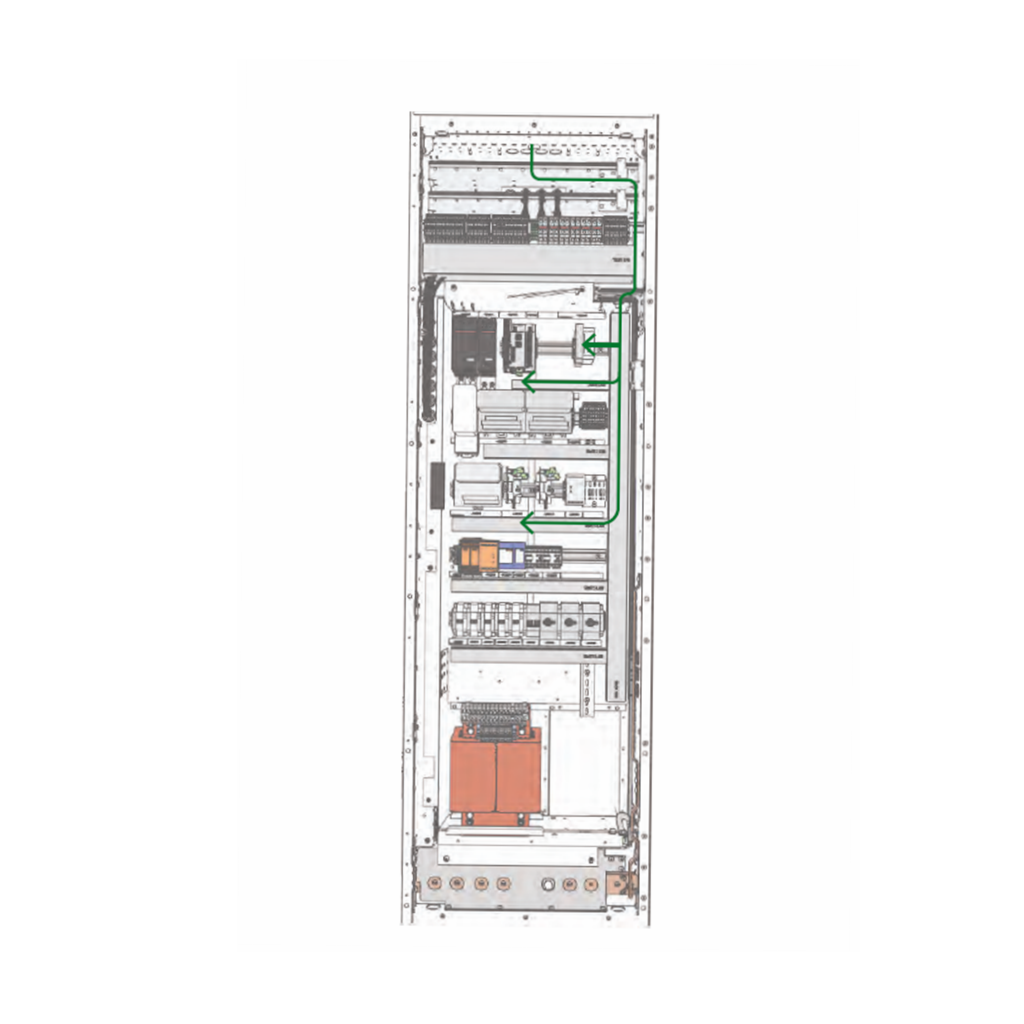

ABB GJR5253100R0220 07KT98 Advant Controller 31 Basic Unit

Basic Information

Model and series attribution: Model GJR5253100R0220 belongs to ABB's 07KT98 Advant Controller 31 series. This model has a specific functional position in ABB's controller product line and is used as a basic control unit in industrial automation control systems.

Possible origin: The origin is not clear at the moment, but given the global supply of ABB products, the manufacturing process and quality standards should be in accordance with ABB's uniform specifications, ensuring stability and reliability in different application scenarios.

Physical dimensions and weight: dimensions of about 10.0 inches × 4.0 inches × 6.0 inches (25.4cm × 10.2cm × 15.2cm), weighing about 1 pound 16.0 ounces (0.9kg). This size and weight make it flexible in the layout of the control cabinet, able to adapt to different space requirements, and relatively easy to transport and install.

Performance Characteristics

Computing and Storage Performance

Computing power: Although there is no specific mention of the detailed parameters of the processor, as the basic unit of the industrial controller, it should have sufficient computing power to quickly and accurately perform a variety of complex control logic operations, such as logical judgement, arithmetic operations, data processing, etc.. In industrial automation scenarios, this ensures that the system responds to various input signals in a timely manner and generates appropriate control instructions.

Storage capacity: There is usually a certain capacity of storage area for storing user-written control programmes and related data. This allows users to write control programs of varying complexity according to specific industrial application requirements, while storing a large amount of operational data, such as equipment status data, production process data, etc., to provide support for system monitoring, fault diagnosis and data analysis.

Communication interface and protocol compatibility

Communication interface types: Equipped with a variety of communication interfaces, such as Ethernet, RS-232, RS-485 and so on. The Ethernet interface provides high-speed and long-distance data transmission capability, which is suitable for communicating with the upper monitoring system, other network devices or remote servers; the RS-232 and RS-485 interfaces are mainly used to connect with various devices in the field, including sensors, actuators, etc., and realise the close-distance data interaction.

Protocol support: It supports a variety of common industrial communication protocols, such as MODBUS, Profibus and so on. This feature makes it possible to seamlessly interface with devices produced by different manufacturers that conform to these protocols, facilitating the construction of a complete industrial automation communication network. For example, it can be used for data acquisition with various smart meters (e.g. temperature, pressure, flow meter) via MODBUS protocol, or collaborative control with other PLCs, inverters and other devices via Profibus protocol.

Input/Output (I/O) Configuration Features

Abundant I/O channels: A variety of digital and analogue input and output channels are available. The digital input channels can receive signals such as switching signals (from pushbuttons, limit switches, etc.) and digital sensor signals (e.g. photoelectric sensors, proximity switches); the digital output channels can be used to control digital devices such as relays and indicators. The analogue input channels are able to acquire analogue signals (e.g. 4-20mA current signals or 0-10V voltage signals) corresponding to physical quantities such as temperature, pressure, flow, etc.; the analogue output channels can be used to control control valves, inverters and other devices requiring analogue signals to drive them.

Flexible I/O Configuration: The functions of these I/O channels can be flexibly adjusted according to specific application scenarios and control requirements. Users can define the specific function of each channel through software programming or hardware settings (e.g., jumpers, dip switches, etc.). For example, an analogue input channel can be configured to receive a specific range of voltage signals for level measurement, or a digital output channel can be set to actuate a motor-starting relay under specific conditions.

Reliability and environmental compatibility

Reliability Guarantee: The use of high-quality electronic components and advanced manufacturing processes helps to ensure the reliability of the product during long-term operation. In industrial environments, equipment may face unfavourable factors such as electromagnetic interference, mechanical vibration, temperature changes, dust, etc. The controller is designed to effectively resist these interferences, reduce the probability of failure, and ensure the stable operation of the system.

Good environmental adaptability: able to work normally in a wide range of operating environmental conditions, although the specific operating temperature, humidity and other parameters may not be explicitly given, but generally take into account the harsh environmental conditions common to industrial sites. Whether it is a high-temperature production workshop, or a low-temperature outdoor equipment control scene, or a high humidity environment, it should be able to maintain stable performance to ensure the normal industrial production process.

Application Areas

Industrial automated production line control: In automobile manufacturing, machining, electronic manufacturing and many other industrial automated production lines, it plays a key control role. For example, in the automobile assembly line, it can control the precise operation movement of the robot, the speed and start/stop of the conveyor belt, the parameter settings of the welding equipment, etc., so as to realise the coordinated operation of the production line equipments, thus improving the production efficiency and product quality.

Process control applications: In the chemical, petroleum, pharmaceutical and other process control industries, used to accurately monitor and control a variety of process parameters. By connecting temperature sensors, pressure sensors, liquid level gauges and other detection equipment, real-time collection of process parameter data, and then according to the pre-written control strategy, control control valves, pumps and other executive equipment, to ensure that the production process is carried out in safe and stable conditions, to ensure the consistency of product quality and the safety of the production process.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923