K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Manufacturers

ABB

Model(s)

ABB Advant Controller 31, ABB Advant OCS, ABB Procontic, ABB Procontic CS31

Estimated Shipping Size

Dimensions: 4.0" x 3.0" x 5.0"

(10.2 cm x 7.6 cm x 12.7 cm)

Weight: 0 lbs 12.0 oz (0.3kg )

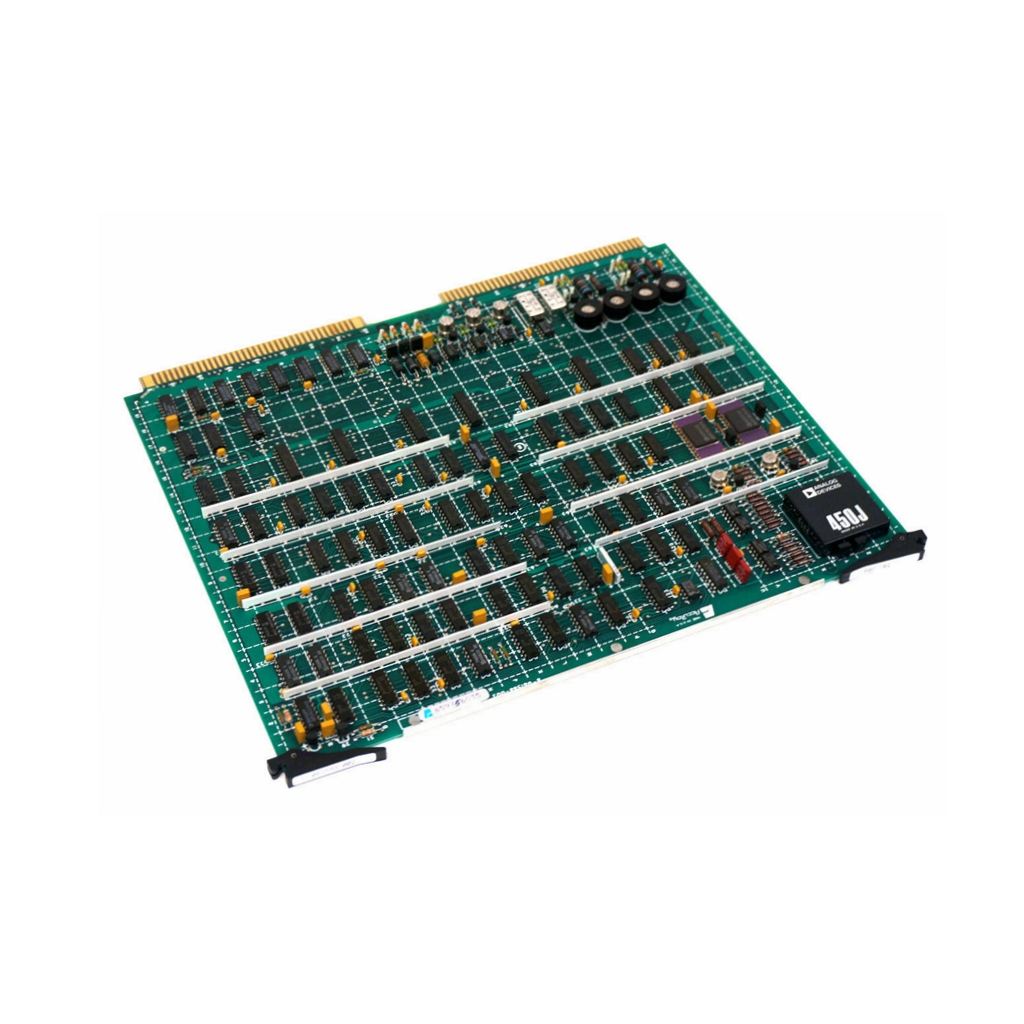

ABB GJV3075801R0001 AS-i Coupler Module

Basic information

Model No.: GJV3075801R0001, clearly identifies the specific model of the product in ABB product line, through which you can accurately obtain detailed information about the product's technical specifications, scope of application and other information.

Name: AS-i Coupler Module, which indicates that it is a coupler module in AS-i network, mainly used to connect AS-i slave devices with the upper control system to achieve data transmission and interaction.

Functional characteristics

Signal conversion and transmission: It can convert signals between the AS-i network and the higher-level control system. It converts the AS-i signals sent by the slave devices into a signal format suitable for processing by the control system, and also converts the command signals sent by the control system into AS-i signals for accurate control of the slave devices. For example, analogue or digital signals collected by sensors are converted and transmitted to a control system such as a PLC, or control commands from a PLC are converted and transmitted to a slave device such as an actuator.

Network Expansion and Connection: As a key component of the AS-i network, it enables network expansion and connection of multiple AS-i slave devices. It provides multiple AS-i interfaces to easily connect multiple slave devices to the AS-i network, thus increasing the number of input and output points of the system and meeting the demand for monitoring and controlling a large number of devices in complex industrial control sites.

Data Processing and Optimisation: Processes and optimises the transmitted data to ensure its accuracy and reliability. In the process of data transmission, it can filter and check the signal to remove interference signals and improve data quality. At the same time, it can also cache and pre-process the data to reduce the burden on the control system and improve the overall performance of the system.

Diagnostic and monitoring function: It has certain diagnostic and monitoring functions, and can monitor the operation status of AS-i network and the working status of slave devices in real time. When there is a fault in the network or an abnormality in the slave equipment, it can send out an alarm signal in time and provide detailed fault diagnosis information to help maintenance personnel quickly locate and eliminate the fault, reduce system downtime and improve production efficiency.

Application Fields

Industrial automated production line: In automated production lines such as automotive manufacturing, electronic manufacturing, etc., it is used to connect various sensors, actuators and other equipment to the control system. For example, connecting temperature sensors, pressure sensors, photoelectric sensors, etc. on the production line to the AS-i network, transmitting sensor data to the PLC through the coupler module to realise real-time monitoring of the production process; at the same time, transmitting PLC's control commands to the motor drives, pneumatic valves, and other actuators, to realise precise control of the production equipment and ensure the efficient and stable operation of the production line.

Logistics and Warehousing System: In logistics automation systems, such as automated three-dimensional warehouses, automatic sorting systems, etc., it can be used to connect the goods detection sensors on the shelves, the position sensors of the stacker cranes, the motors and sensors of the conveyor lines and other equipment. The AS-i Coupler Module realises the communication between these equipments and the control system, so as to achieve the automatic storage, retrieval and sorting of goods, and improve the efficiency and accuracy of logistics.

Intelligent Building System: In the HVAC (heating, ventilation, and air conditioning) system and lighting system of an intelligent building, temperature sensors, humidity sensors, light level sensors, air conditioning units, lighting fixtures, and other devices can be connected to the AS-i network. Through the coupler module to achieve data interaction between sensors and control systems, intelligent monitoring and control of the environment in the building to improve energy efficiency and comfort.

Process control field: In chemical, petroleum, pharmaceutical and other process control industries, it is used to connect various process parameter detectors and control valves, pumps and other equipment. For example, the flow meter, level meter, pressure gauge and other instrument data transmission to the control system, at the same time, the control system on the valve opening, pump start and stop control instructions transmitted to the corresponding equipment, to ensure the safe and stable operation of the production process.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923