K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Manufacturers

ABB

Model(s)

ABB Advant Controller 31, ABB Advant OCS

Additional Information

07CR41 Advant Controller Basic Unit - 24VDC 8 24VDC Inputs 6 Relay Outputs

Estimated Shipping Size

Dimensions: 4.0" x 4.0" x 5.0"

(10.2 cm x 10.2 cm x 12.7 cm)

Weight: 1 lbs 13.0 oz (0.8kg )

Tariff Code: 8538907080

Country of Origin: Sweden

Ships from Webster NY, USA

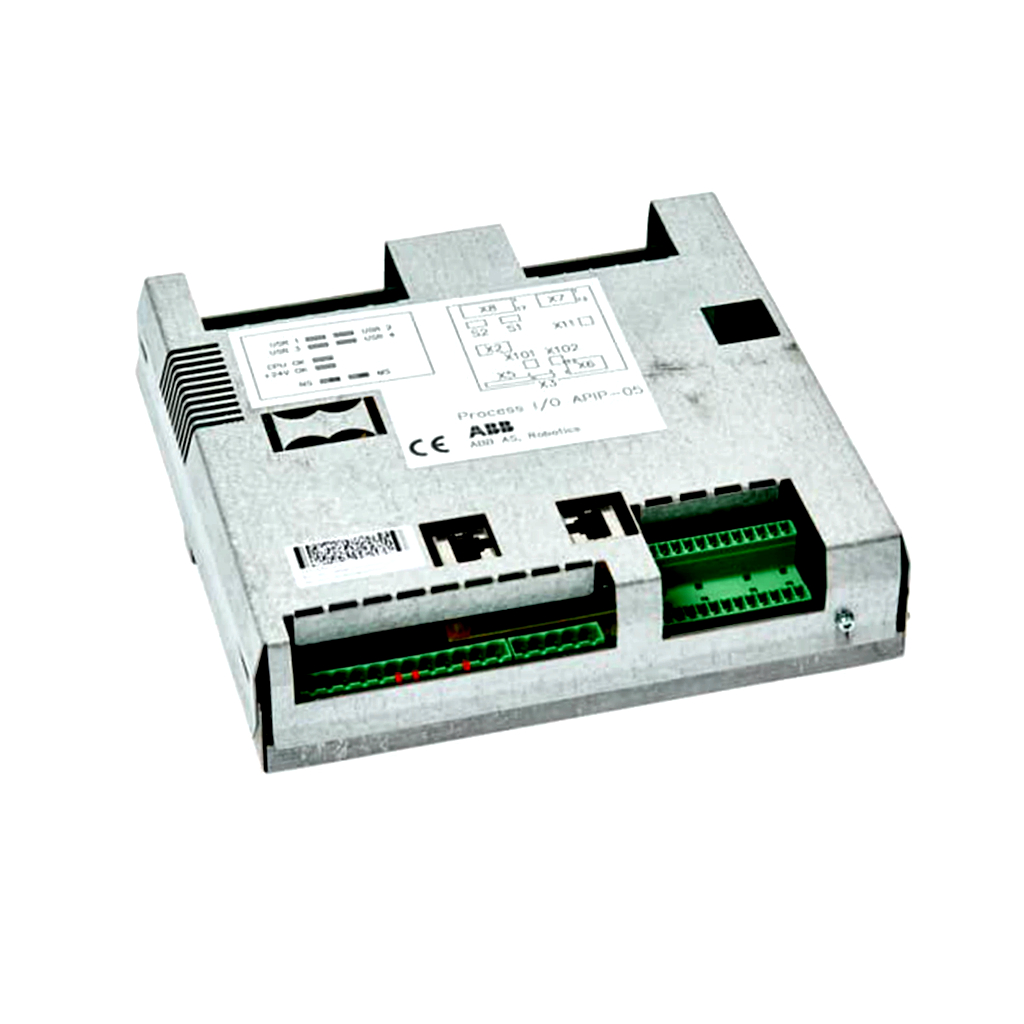

ABB ISBP260520R1001 07CR41 Advant Controller Basic Unit - 24VDC

Basic Information

Model No. ISBP260520R1001 07CR41, an ABB Advant Controller Basic Unit, operating at 24VDC, is a key component in industrial automation control systems used to control and manage a wide range of industrial processes and equipment.

Performance features

Control Functions

Powerful Logic Processing: The Controller Basic Unit is capable of performing complex logic operations and control algorithms. It can process input signals and output corresponding control signals according to pre-programmed rules and conditions to achieve precise control of industrial equipment. For example, in an automated production line, it can control the starting and stopping of motors and the speed of conveyor belts through logical judgement according to the information of product position and quality detected by sensors.

Multi-tasking capability: It supports multi-tasking and is capable of running multiple control programmes or tasks at the same time. This makes it possible to manage multiple devices or multiple control links in parallel, improving the overall efficiency of the system. For example, in a complex chemical production process, it can simultaneously monitor multiple parameters such as reaction temperature, pressure and flow rate, and perform the corresponding control operations respectively.

Input/Output Interface

Rich I/O interfaces: Equipped with various types of input and output interfaces, including digital input (DI), digital output (DO), analogue input (AI) and analogue output (AO) interfaces. These interfaces can be conveniently connected to a variety of sensors (such as temperature sensors, pressure sensors, etc.) and actuators (such as motors, valves, etc.) to achieve the acquisition of signals and the output of control commands. For example, the analogue input interface receives signals from temperature sensors and then controls the power of the heating device through the analogue output interface, thus achieving precise control of the temperature.

Interface characteristics: The I/O interface has a high anti-interference capability and can work stably in the complex industrial electromagnetic environment. At the same time, the electrical parameters of the interface (such as voltage, current, etc.) are in line with industrial standards, which ensures good compatibility with external devices and the accuracy of signal transmission.

Power supply characteristics

Stable 24VDC power supply: It works under 24VDC power supply, which is more common in industrial environments and has a certain degree of safety and stability. The controller can work normally within a certain voltage fluctuation range and is usually equipped with an internal power protection circuit to prevent overvoltage, undervoltage and other abnormal conditions from damaging the controller. For example, when the power supply voltage fluctuates briefly, the power protection circuit can maintain the normal operation of the controller to avoid data loss or system failure.

Reliability and Stability

High-quality components and manufacturing process: The use of high-quality electronic components and advanced manufacturing process ensures the reliability and stability of the controller. Its circuit boards undergo strict quality testing, and the selection of components takes into account the long-term use requirements of industrial environments, such as resistance to high temperature and humidity changes. During long-term operation, it can effectively reduce the probability of failure and ensure the continuity of industrial production.

Redundancy design (if any): Some models may have redundancy features, such as dual power inputs, dual processors and other designs. When one component fails, the redundant component can immediately take over the work, avoiding system downtime and further improving system reliability. This redundancy design is very important in industrial production scenarios (e.g., petrochemical, power systems, etc.) that require high reliability.

Application Areas

Industrial automated production lines: In automated production lines in automotive manufacturing, machining, electronic equipment manufacturing and other industries, it is used to control the operation of various production equipment. For example, controlling the action sequence of robots, the speed and beat of the production line, the operation of quality inspection equipment, etc., to ensure the efficient and precise operation of the production line.

Process control industry: In the process control field of chemical, petroleum and pharmaceutical industries, it is used as the core controller to control the temperature, pressure, liquid level, flow rate and other key parameters of the reaction kettle. It can accurately adjust the opening degree of various valves, pump speed, etc. according to the process requirements to ensure the safety, stability and high efficiency of the production process.

Intelligent building system: It plays a role in the automation control of HVAC (heating, ventilation and air conditioning) system, lighting system and water supply and drainage system of intelligent buildings. For example, it controls the temperature adjustment of air-conditioning units, the brightness control of lighting fixtures, and the starting and stopping of water pumps, etc., so as to realise the intelligent management of the environment and the rational use of energy in buildings.

Transportation field: in the rail transit system, it can be used in the train control system, platform screen door control system, etc.; in the traffic signal control system, it is used to control the switching and timing of traffic signals to improve the efficiency and safety of transportation.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923