K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

advantage

Maximizing normal operating time

The best in class high availability control system that supports and

Perform maintenance and eliminate single point of failure

Intelligent remote I/O factory control shutdown

GE IC695CEP001 RX3i carrier board equipped with embedded PROFINET

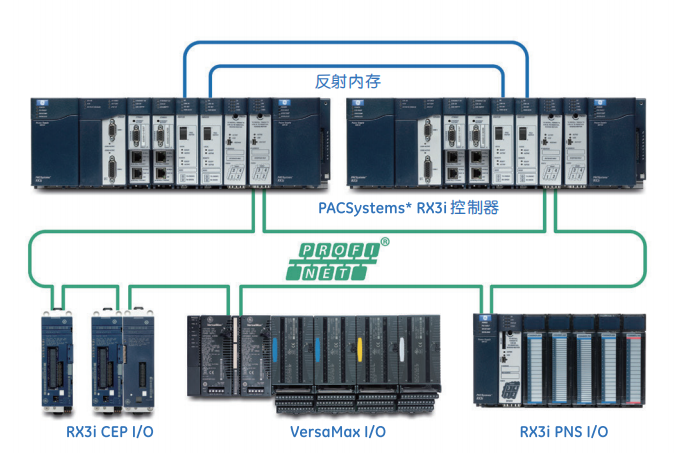

PACSystems * Redundant System Based on PROFINETA solution to maximize the normal running time of critical task applications

Unplanned downtime causes annual impact on the global process industry

advantage

Reduce overall cost of ownership

A loss of one billion dollars. Time is cost. When

Maximizing normal operating time

Built in fiber optic and media conversion functions, reducing purchases

In today's highly competitive market environment, it is necessary to adopt

Can maximize the normal operation of critical task applications

● Best in class high availability control system, supporting and

Number of external devices configured and maintained

Travel time, providing high availability for parallel maintenance capability

Perform maintenance and eliminate single point of failure

Equipped with a 4-port Ethernet switch, no external connection required

System, in the process of modifying, troubleshooting, and

Intelligent remote I/O factory control shutdown

● Smaller size, lower power requirements, and shorter setup time

During maintenance, the system does not need to be shut down.

Plug and play

GE Intelligent Platform is committed to producing and operating equipment for you

● Redundant solutions for GE and third-party PROFINET I/O

Using redundant PACSystems system based on PROFINET

Business or controlled processes provide industrial Internet

Case configuration tool

Maximize the normal operation time of the system

Solution. GE's high availability system will be outstanding

Drag and drop to add PROFINET devices to meet specific applications

The critical task system has malfunctioned, which may affect the company's operations

Connect equipment, personnel, and data to ensure task completion

demand

Profit, reputation, and potential health or environmental hazards. stop

Key applications meet the requirement of maximizing normal running time

● Add operator interface for GE intelligent platform, SCADA

One minute can cause hundreds or thousands of dollars in losses.

Please.

Create a custom integration platform with analysis tools

Depending on the application location or the nature of the downtime, the downtime may vary

Relying on GE's market leadership position and critical role in mission readiness

It may extend to several hours, or even days.

security

Decades of expertise in power supply and critical cooling solutions

Technological accumulation, PACSystems based on PROFINET

By obtaining certification from the GE Information Security Technology Center, it is possible to reduce

High availability systems help you maintain continuous production operations,

Prevent equipment or productivity losses, and prevent unplanned incidents

A redundant system is a flexible, intelligent, and highly available system

The risk of cyber attacks

Shutdown or potential hazards that make your investment worthwhile.

Control system, by simplifying configuration, operation, and maintenance

Through Achilles testing, weak information security can be improved

Process to ensure maximum normal running time, while

link

PACSystems based on PROFINET on GE Intelligent Platform

It can reduce the total cost of ownership (TCO).

Real time monitoring of network health status

The redundant system further enriches its high availability solutions

Solution product line, the best high performance among similar products

The system has been carefully crafted to meet your critical task requirements

connect

Capable of architecture and equipped with PROFINET communication system, greatly reducing costs

The following requirements for the application:

Advanced data collection, storage, and retrieval functions help

Reduced overall cost of ownership and simplified the requirement for 24 hours a year

Maintain continuous production operation

Help achieve process visualization, control, and analysis

High availability control system for applications that run continuously without interruption

Prevent equipment or product loss

Local and remote visibility and workflow management

Configuration, maintenance, and operation.

Reduce unplanned downtime or potential risks

Can achieve cross functional collaboration

Connect devices, data, and personnel for optimal performance

performance

Minimize the frequency and impact of system failures to the greatest extent possible

The Medium Redundancy Protocol (MRP) using a circular topology structure minimizes network failures to the greatest extent possible

The likelihood and impact of occurrence. High speed fault switching ensures that the system operates at the latest

In terms of system input, further improve production quality. When modifying or updating the system, there is no

Shutdown is required.

The redundant PACSystems system based on PROFINET ensures system continuity through the following measures

function:

Failure and recovery of any CPU

Fault and recovery of I/O nodes

Cable breakage and recovery of circular network

Cable breakage and recovery when I/O nodes are in maintenance mode

Cable breakage and recovery within one or two redundant CPU links

Start the system when the independent CPU is in 'run' mode

Change hardware configuration or logic

Improve system performance

The system achieves high-performance and fast CPU synchronization through a reliable reflective memory (RMX) network, which can

Capable of processing large amounts of data using CPUs located 300 meters apart, and with SMF RMX, this distance can be extended

Up to 10 kilometers.

Gigabit level I/O networks process process process data through wider and faster pipelines. Built in 4 ports

Ethernet switches do not require external network connections, thereby reducing space requirements and minimizing

Power consumption and cost have shortened the setup time.

Tailor made

PACSystems redundant system based on PROFINET provides simple and easy-to-use scalability.

Flexible and user-friendly systems can be configured according to the specific normal operating time requirements of your business.

Open architecture allows for the mixed use of redundant I/O, meeting the requirements of size, performance, environmental friendliness, and node distance

Application requirements in terms of price points. Use other Ethernet protocols to connect operator interfaces, etc

When using local devices, there is no need to add additional hardware, which will not affect the certainty of controlling the network

Integrity. By determining the priority of PROFINET traffic on a mixed protocol I/O network

The above characteristics are present.

Simple configuration

The integration and implementation of the system are very convenient and fast. The system provides access to critical infrastructure infrastructure

Use the control platform. Single point, name based configuration can be completed using a set of simple tools, reducing

Short setup time.

Gain insights into critical systems

The system provides critical data that can be used to analyze system performance and downtime events, enhancing reliability

Sex. Capable of centralized display of system status, providing remote fault diagnosis capability, fast and efficient

Share data with operators and maintenance personnel.

Reduce complexity and lower costs

The system utilizes built-in Ethernet switches and media conversion functions to provide external point-to-point plugging and unplugging

Seamless support for mixed network media types with seamless connectivity.

This can reduce the number of devices that need to be purchased, the number of external devices that need to be configured, and the requirements

The number of components to be maintained. Using a redundant PACSystems system based on PROFINET to solve the problem

The solution can reduce the cost of high availability control systems by up to 30% throughout the entire lifecycle.

PACSystems Redundant System Based on PROFINET

Advantages of ROFINET

PROFINET is a leading industrial Ethernet protocol that provides solutions for various levels of industrial systems

Provide fast, simple, and cost-effective connections. This high-speed, open standard is easy to use

Mix and match various types of I/O, modify according to the requirements of the shortest downtime, convenient

Integrate third-party products.

Up to 60% of the costs in automation projects involve the laying, grounding, and installation of I/O wires

verification. Using Ethernet communication, only one Ethernet cable is needed to connect back to the main control

The device can shorten the wire length for remote I/O and local connection verification, significantly reducing the height

The cost of building a functional system.

PROFINET provides:

Wide coverage including discrete and process applications

Bring high-performance multi-level real-time control to large traffic

Open standards, rapidly growing suppliers, and PROFINET device ecosystem

By using PROFINET as the communication protocol, the high availability system of GE Intelligent Platform can improve

Supply:

Single point configuration and name based configuration

Simple point-to-point network connection

High speed execution and integrated switching

Built in switches and fiber optic capabilities reduce installation and maintenance costs

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923