K-WANG

Xycom 2005 - 9-inch LCD Upgrade Kit for CRT with Cable Kit

The Xycom 2005 is a robust and versatile automation controller designed to meet the demanding requirements of the power industry, petrochemical sectors, and general automation applications. Engineered with precision and reliability in mind, the Xycom 2005 offers an impressive array of technical features that make it a standout choice for industrial control systems requiring seamless integration, high durability, and consistent performance.

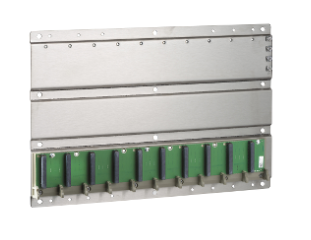

One of the key technical highlights of the Xycom 2005 is its extensive input/output (I/O) capacity. It supports a wide range of digital and analog I/O modules, enabling it to handle complex control tasks with ease. The 2005’s modular design allows for scalable I/O configurations, accommodating up to 128 discrete inputs and outputs, along with multiple analog input channels capable of high-resolution signal processing. This flexibility ensures that the controller can be tailored precisely to the needs of various automation environments, from monitoring critical parameters in power plants to managing process variables in petrochemical refineries.

Durability is another cornerstone of the Xycom 2005’s design. Built to withstand harsh industrial environments, it features ruggedized components with high resistance to shock, vibration, and temperature extremes. The enclosure meets stringent IP ratings, making it suitable for deployment in outdoor or hazardous locations where dust, moisture, or corrosive substances are present. This durability translates to reduced downtime and maintenance costs, which are essential factors in industries where operational continuity is paramount.

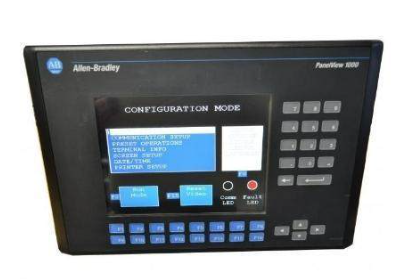

Performance-wise, the Xycom 2005 excels with its fast processing capabilities and real-time data handling. It supports advanced communication protocols including MODBUS, Ethernet/IP, and proprietary Xycom interfaces, ensuring smooth interoperability with other automation systems and devices. The controller’s low latency and high-speed scanning cycles allow for precise control and rapid response to dynamic conditions, which is critical in power generation control systems and petrochemical process automation.

In real-world scenarios, the application of the Xycom 2005 in the power industry is notable for its ability to manage turbine controls, monitor generator outputs, and integrate protective relaying functions. In petrochemical plants, the 2005 effectively handles complex batch processing, chemical dosing control, and safety interlocks, maintaining both efficiency and compliance with safety standards. For general automation, it is widely used in manufacturing lines, material handling systems, and environmental monitoring setups, where its adaptability and reliability are highly valued.

When compared to other Xycom automation products, the 2005 stands out for its balance of scalability and ruggedness. For instance, models like the Xycom 8500 and 8500-031253601 are known for their high-density I/O but are more suited to less harsh conditions. The Xycom 4860/VME and Xycom XVME-428/1 offer VMEbus-based solutions ideal for embedded systems but lack the modular field I/O flexibility of the 2005. Similarly, while the Xycom 9450 / 99298-098 and Xycom 9462-015214001 provide advanced processing power, the 2005’s simpler architecture ensures easier maintenance and faster deployment in field environments. The Xycom 3115-011111101 / 9001 and Xycom 3515-KPM are excellent for specific applications but do not match the 2005’s comprehensive I/O capacity and rugged design.

Alongside the Xycom 2005, we also offer complementary models such as the Xycom 5019T-SER for serial communications, the Xycom XVME-688 / 70688-011 / 71688C-001 for VMEbus expansions, and the Xycom GP2500-TC41-24V touchscreen operator interface to provide enhanced human-machine interaction. The Xycom XVME-220 and XVME-976 serve as powerful processing modules in integrated automation systems, while the Xycom 4870 and Xycom 84091A / 240276 add specialized I/O capabilities. These models, when combined, create a cohesive suite of Xycom automation products tailored to diverse industrial needs.

In summary, the Xycom 2005 represents a pinnacle of design in industrial automation controllers, delivering unmatched input/output capacity, rugged durability, and reliable high-speed performance. Its proven track record in the power industry, petrochemical plants, and general automation underscores its versatility and robustness. Whether deployed as a standalone unit or integrated within a broader Xycom automation ecosystem that includes models like the 8500, 4860/VME, and XVME series, the 2005 ensures optimal control and operational excellence. For engineers and automation specialists seeking dependable solutions, the Xycom 2005 remains a top choice for critical industrial applications.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|