K-WANG

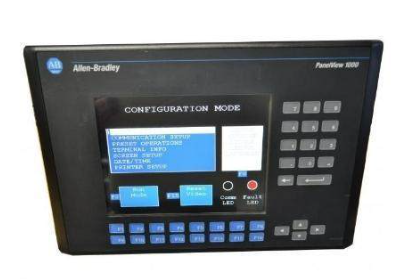

Xycom 3515 - Operator Interface

The Xycom 3515 stands out as a rugged and highly reliable automation controller specifically engineered to meet the demanding requirements of the power industry, petrochemical plants, and general automation applications. This model delivers superior performance through its robust input/output capacity, exceptional durability, and efficient processing capabilities, making it a cornerstone in environments where precision and uptime are critical.

Key technical features of the Xycom 3515 include a versatile I/O configuration that supports up to 128 digital inputs and outputs, along with multiple analog input channels. This extensive I/O capacity ensures seamless integration with a wide array of sensors and control devices, enabling detailed process monitoring and control. The controller is built to withstand harsh industrial conditions, featuring a ruggedized chassis resistant to shock, vibration, and extreme temperature variations, which are common in petrochemical refineries and power generation stations. Performance-wise, the Xycom 3515 operates on a high-speed processor architecture that supports real-time data acquisition and rapid execution of complex automation tasks, reducing latency and enhancing operational responsiveness.

In real-world usage, the application of the 3515 in the power industry is particularly notable. It is frequently deployed in control rooms managing turbine operations, generator synchronization, and load balancing. Its precise control functions reduce downtime and optimize energy output. In petrochemical environments, the 3515 excels at automating critical safety systems and process controls, such as pressure and temperature regulation, ensuring compliance with stringent safety standards. For general automation, this model’s flexible I/O and durable design allow it to be used in manufacturing lines, material handling systems, and facility monitoring, delivering consistent performance even in demanding production environments.

When compared to other Xycom automation products, the 3515 holds several unique advantages. Unlike the Xycom 81987-001-D / 1805 and the Xycom 9485 / 9485-27A131701, which are optimized for more specialized tasks with limited I/O scalability, the 3515 offers a broader input/output range suitable for complex multi-variable applications. Compared to the Xycom 3512 KP and Xycom 3512-01A104003, which share a similar form factor, the 3515 offers enhanced processing speed and updated firmware support for newer protocols, making it future-proof for evolving automation standards. Additionally, its rugged design surpasses that of models like the Xycom 84091A / 240276 and Xycom 9487, which are less tolerant of extreme industrial environments.

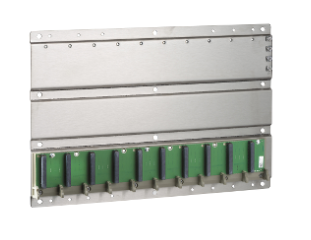

Alongside the Xycom 3515, we also offer complementary models such as the Xycom XT1502T / XT1502T-CU13/A, which serves as a high-performance operator interface, and the Xycom XVME-566 / 70566-001, a powerful VMEbus I/O module that pairs well with the 3515’s control capabilities. For applications requiring enhanced networking and remote input/output modules, the Xycom RIO II / AES-0262 / VE00085696 provides expanded connectivity options. The Xycom 3015T and Xycom 3612T also provide alternative controller options for users who require different form factors or additional CPU power. Meanwhile, the Xycom 4810ERO is ideal for embedded system integration in automated machinery, complementing the 3515 in complex automation setups.

The Xycom 3515’s compatibility with a broad ecosystem of automation components, including the Xycom 8320 / 94321-002 keypad modules and the Xycom XVME-230 I/O cards, allows system integrators to build fully customized solutions tailored to specific industrial needs. Its ability to seamlessly interface with models like the Xycom 9450 / 4664 and Xycom 9450 / 4668 further enhances its versatility in large-scale automation projects.

In summary, the Xycom 3515 represents a robust, scalable, and high-performance solution within the Xycom automation products lineup. Its application of 3515 in power industry, petrochemical, and general automation settings highlights its adaptability and reliability under demanding conditions. Whether managing critical safety controls in a refinery or optimizing energy distribution in a power plant, the 3515 delivers the precision and resilience required by modern industrial automation. Paired with complementary models such as the Xycom XT1502T, XVME-566, and RIO II, it forms the backbone of advanced, integrated automation systems designed to improve operational efficiency and reduce downtime.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|