K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

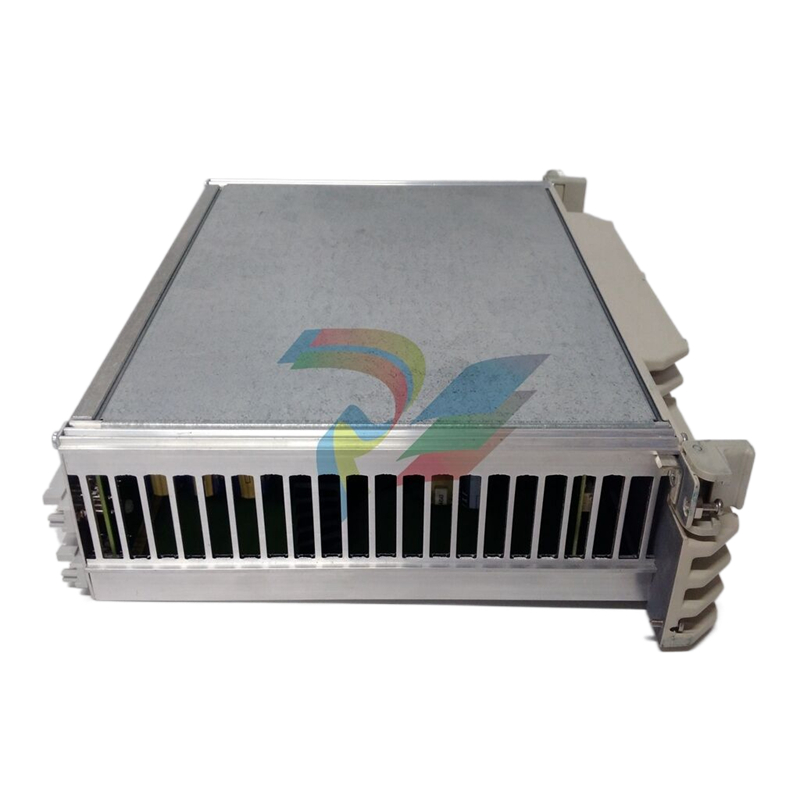

ABB SMS01 ETSI Stepper Motor Module

Basic information

Place of origin: Sweden.

Weight: about 3kg.

Performance characteristics

High-precision control: It can realise precise control of the stepper motor and ensure that the speed, steering and position of the motor are controlled with high precision, which meets the requirements for precise motion control in various industrial automation applications.

Multiple control modes: Supporting multiple control modes, it can flexibly adapt to different working scenarios and control requirements, such as speed control mode, position control mode, etc. The control modes can be switched through simple parameter settings, which is convenient for users to adjust according to actual applications.

Strong compatibility: Designed with compatibility with other ABB automation equipment and systems in mind, it can be seamlessly integrated into ABB's overall automation solutions to achieve system synergy and improve the performance and reliability of the entire system.

High reliability: the use of high-quality electronic components and advanced manufacturing processes, with good anti-interference ability and stability, can be in the harsh industrial environment of long-term stable operation, reduce production interruptions caused by equipment failure and maintenance costs.

Easy to install and maintain: the structure of the module is reasonably designed, easy and quick to install, and at the same time, it has perfect fault diagnosis and alarm function, which can promptly and accurately prompt the fault information when there is a malfunction, so as to facilitate the maintenance personnel to quickly locate and solve the problem, and to reduce the difficulty of maintenance and time cost.

Working Principle

The module receives control signals from the controller, these signals contain control instructions for the speed, steering and position of the stepper motor. The internal circuitry of the module converts these digital control signals into pulse signals and direction signals suitable for stepper motor drive, and then amplifies the signals to a level sufficient to drive the stepper motor through a power amplifier circuit, thus controlling the stepper motor to carry out precise movements in accordance with the preset requirements.

Application Fields

Industrial automated production line: In the automated production line, it is used to control the precise movement of all kinds of conveyors, robotic arms, workstations, etc., to achieve the automated production, assembly, testing and other processes, and to improve production efficiency and product quality.

Packaging machinery: such as in packaging machinery for food, pharmaceuticals, daily necessities, etc., to control the movement of packaging materials such as conveying, cutting, sealing, etc., as well as the operation of products such as measuring, filling, labelling, etc., to ensure the accuracy and stability of the packaging process.

Robotics: As the key component of robot joint drive, it controls the movement of robot's arm, leg, waist and other joints, realises the robot's precise grasping, handling, operation and other actions, and improves the robot's working precision and flexibility.

CNC machining equipment: in CNC machine tools, engraving machines and other CNC machining equipment, used to control the feed movement of the tool, to achieve accurate processing of the workpiece, to ensure machining accuracy and surface quality.

Textile machinery: for example, controlling the roller speed and needle movement of textile machines to achieve precise feeding of yarn and weaving of fabrics to improve the quality and productivity of textile products.

FEATURES

• Process Station with integrated fieldbus capability

• 4 high-speed fieldbus lines

• Supports different fieldbus types, even simultaneously: PROFIBUS-DP, up to 12 MBd Modbus CAN Foundation Fieldbus H1 (with LD800 HSE)

• Easy engineering: fully integrated in Control Builder F

• One unified database for field devices shared by the control level and the Human System Interface (HSI)

• Module recognition with factory and operational parameters

• Comprehensive diagnostics for proactive maintenance

• Compact, rugged design

• Front panel connectors

• DIN Rail (C-rail) or wall mounting for easy installation

• Ambient temperature 0-60 °C (32-140 °F) with temperature monitoring

• EMC certification according to EN50082

• Certification: CE, NAMUR, CSA, UL, EN61000-6-2.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923