K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

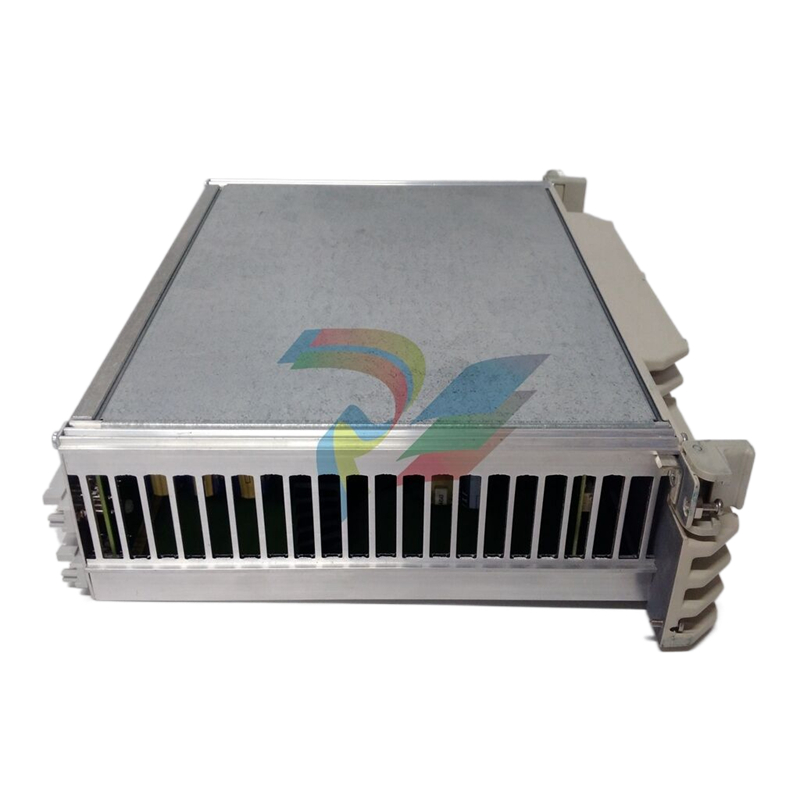

ABB SPASI23 Analog Input Module

Basic information

Place of origin: Sweden.

Dimensions: approx. 144 mm x 127 mm x 25 mm.

Weight: approx. 1kg.

Performance features

Highly Accurate Measurement: With 16-bit resolution and an accuracy of ±0.1% of full scale, it is able to accurately measure small changes in the input signal, ensuring that the system can accurately collect and monitor analogue data.

Multiple Input Types: Supports universal analogue input types, including voltage (e.g. ±10 V, ±5 V, 0-10 V, 0-5 V, etc.), current (e.g. ±20 mA, 4-20 mA, etc.), as well as thermocouples (e.g. J, K, T, E, R, S, B, etc.), which meets the needs of different sensors and field devices for signal access.

Multi-Channel Inputs: Provides 23 analogue input channels, allowing the system to monitor and control multiple process variables at the same time, increasing the system's monitoring and control capabilities and making it suitable for complex industrial automation application scenarios.

High sampling rate: Sampling rate up to 100 Hz, can quickly collect analogue signal data, reflecting the changes in the field signals in a timely manner, to provide strong support for the control system's rapid response.

Electrical isolation: with 250 V AC electrical isolation characteristics, effectively prevent external interference and faults on the module and control system, improve system stability and reliability.

Principle of operation

The SPASI23 module receives analogue signals from various sensors or field devices, such as voltage signals from temperature sensors, current signals from pressure sensors or thermal potential signals from thermocouples, through its input channels. These analogue signals are amplified, filtered and converted to digital signals by the internal signal conditioning circuitry of the module and then transmitted to the host computer or control system via the communication interface for further processing and analysis.

Application Fields

Process control: In the chemical, pharmaceutical, food and beverage industries, it can be used to monitor and control temperature, pressure, flow, liquid level and other process variables to ensure the stable operation of the production process and product quality consistency.

Industrial automation production line: Widely used in various industrial automation production lines, such as automotive manufacturing, machining, electronics manufacturing, etc., for the collection and processing of analogue data, to achieve accurate control and condition monitoring of production equipment.

Energy management: in the power, heat and other energy production and distribution system, can be used to monitor the current, voltage, power and other parameters, to achieve effective management and optimal distribution of energy.

Environmental monitoring: It can be used to collect and monitor environmental parameters, such as atmospheric pressure, temperature, humidity, etc., to provide data support for the environmental control system and ensure that the environmental conditions meet the requirements.

Our Main Brands

· - ABB Advant-800xA,Advant OCS,Bailey Infi 90 and Net 90,H&B Freelance 2000,DSQC Robots,IGCT / IGBT

· - GE General Electric Field Control, Genius I/O, QuickPanel, RX3i PacSystem, Series 90, Series 90, Series VersaMax

· - Allen Bradley Allen-Bradley SLC500, MicroLogix, CompactLogix, ControlLogix, PLC-5, Panel View,

· - Bently Nevada 3300 System, 3500 System

· - Honeywell 7800 Series, FSC, IPC, Mxopen, TDC 2000, TDC 3000, Experion PKS(C200,C300)

· - Yokogawa Centum CS - Centum VP, Centum XL - micro XL, FA-M3, ProSafe-PLC

· - Ovation, Foxboro, EPRO, Emerson DeltaV, Fuji, Siemens, HIMA, Prosoft, Invensys Triconex, ICS TRIPLEX, Woodward, Bachmann, Schneider

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|