K-WANG

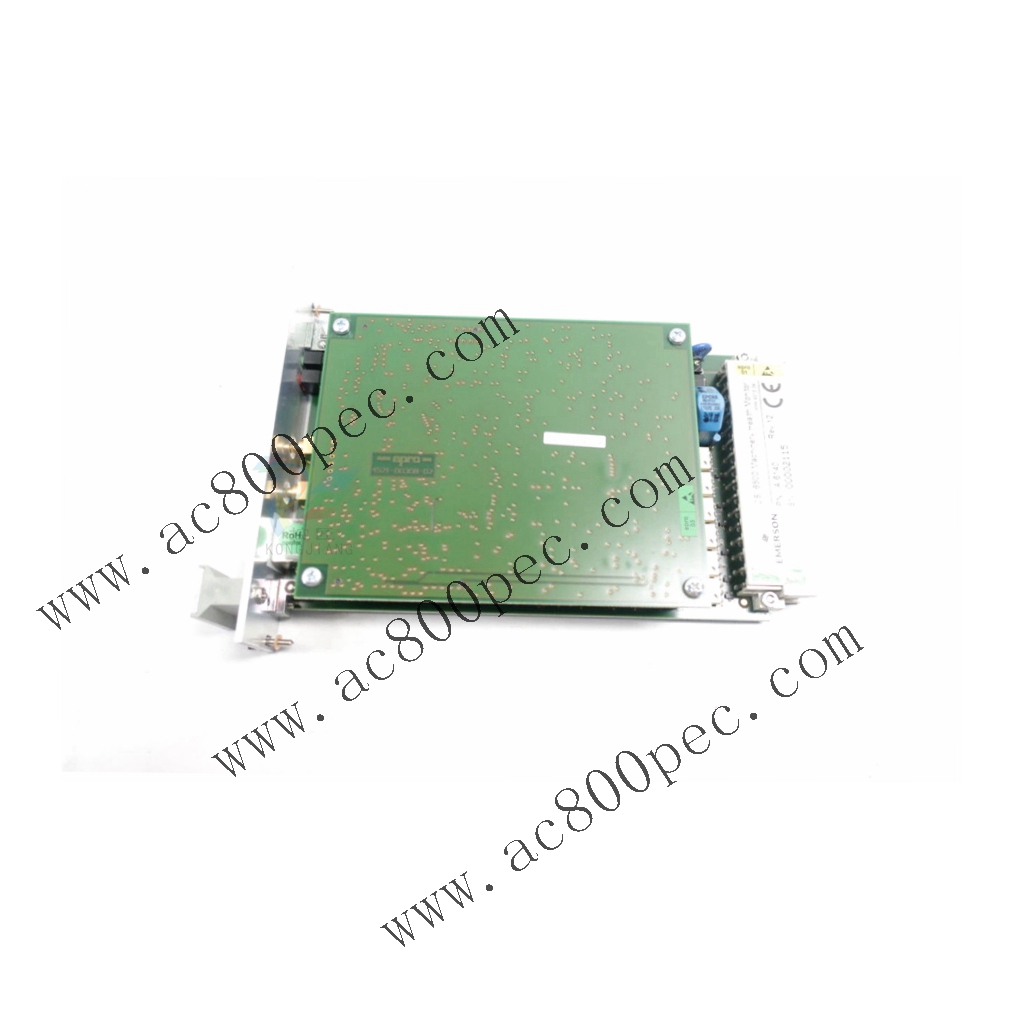

EMERSON PLC - 5X00226G3, Industrial Control Module

The EMERSON PLC stands as a cornerstone in the realm of industrial automation, delivering unparalleled performance and reliability tailored for demanding sectors such as the power industry, petrochemical plants, and general automation processes. Engineered with robust hardware and advanced software integration, the EMERSON PLC offers a comprehensive solution that ensures seamless control, monitoring, and data acquisition with exceptional accuracy and responsiveness.

At the heart of the EMERSON PLC is its impressive input/output capacity, supporting a wide range of digital and analog signals to meet diverse operational requirements. The system accommodates up to 512 I/O points, including both high-speed digital inputs and precision analog channels, ensuring real-time data processing and swift response times critical for high-stakes industrial environments. Its modular design allows for easy scalability, letting operators expand or customize the configuration with minimal downtime. This flexibility is further enhanced by compatibility with EMERSON’s extensive range of interface and communication modules, such as the EMERSON KJ3241X1-EA1 redundant serial interface terminal block and the DeltaV CE4003S2B6 analog input module, thereby broadening its integration capabilities within complex automation architectures.

Durability is another hallmark of the EMERSON PLC, designed to withstand harsh industrial conditions. It features rugged enclosures rated for IP65 protection against dust and moisture, and components built to endure temperature extremes, vibrations, and electrical noise commonly encountered in petrochemical refineries and power generating stations. This resilience ensures continuous operation even in challenging environments, minimizing downtime and maintenance costs. Moreover, the PLC’s advanced diagnostics and self-monitoring features help detect faults early, improving system reliability and safety, which are paramount in sectors such as power generation and chemical processing.

Performance metrics of the EMERSON PLC highlight its rapid processing speed with cycle times as low as 1 millisecond, supporting complex control algorithms and high-frequency data updates. This capability is essential for applications requiring precise motion control or fast feedback loops, such as those managed by the EMERSON M701-06400350A AC drive or the ST1403P Digitax servo drive. The PLC’s seamless integration with these drives facilitates coordinated motor control and energy-efficient operation, enhancing overall system productivity.

In real-world scenarios, the EMERSON PLC excels in managing critical automation tasks. For example, in power plants, it efficiently coordinates turbine control systems, working alongside sensors like the EMERSON PR6423/012-130 CON0211 turbine sensor and velocity sensors such as the EMERSON PR9268/601-000 to optimize performance and safety. In petrochemical facilities, the PLC’s precise control and monitoring capabilities ensure stable process parameters by interfacing with displacement sensors like the EMERSON PR6424/010-140 and eddy current sensors such as the EMERSON PR6423/003-030-CN CON021. These integrations enable operators to maintain tight process control and detect anomalies before they escalate into costly failures.

Compared to other EMERSON automation products, the EMERSON PLC stands out for its balance of scalability, ruggedness, and fast processing power. While models like the EMERSON Ovation 5X00109G01 analog input card or the VE4050S2K1C1 focus primarily on signal conditioning and data acquisition, the EMERSON PLC provides a comprehensive control platform that unifies these functions with advanced logic and communication capabilities. Additionally, the PLC offers superior modularity and ease of integration compared to standalone drives such as the EMERSON M701-03400025A Unidrive M700 or power distribution modules like the EMERSON 5X00500G01, making it an ideal hub for centralized automation control.

Moreover, alongside the EMERSON PLC, complementary products such as the EMERSON CE5009 power supply and the EMERSON MMS6110 system controller can be deployed to create a robust and reliable automation ecosystem. The PLC’s compatibility with various sensor technologies, including vibration sensors like the EMERSON PR 6424/000-021 CON 041 and eddy current sensors such as the EMERSON PR6423/01C-010 CON021, further enhances its utility across different industrial applications.

In summary, the EMERSON PLC is a versatile and rugged automation controller that excels in the application of PLC in power industry, petrochemical, and general automation environments. It delivers high input/output capacity, fast processing speeds, and robust durability, ensuring optimal performance in critical industrial operations. Integrated seamlessly with a wide array of EMERSON automation products, it provides a scalable and reliable solution designed to meet the evolving demands of modern industrial automation. Whether optimizing turbine control with EMERSON PR6423 series sensors or managing motor drives with the M701 AC drive lineup, the EMERSON PLC remains the backbone of efficient and safe industrial automation systems.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|