K-WANG

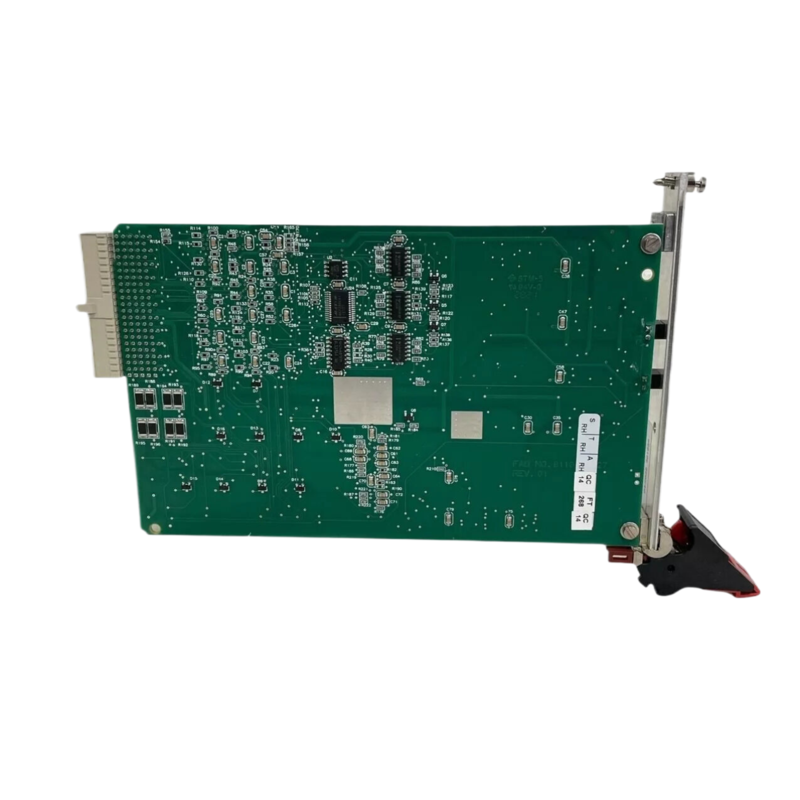

Applied Materials SINGLE COOLDOWN CHAMBER - SINGLE COOLDOWN CHAMBER AMAT

The Applied Materials SINGLE COOLDOWN CHAMBER is a state-of-the-art solution designed to meet the stringent demands of the power industry, petrochemical sector, and general automation environments. Engineered with precision, this chamber provides superior cooldown performance, ensuring efficient thermal management and rapid stabilization of sensitive components. Built with robust materials and advanced thermal regulation technology, the SINGLE COOLDOWN CHAMBER excels in maintaining optimal operating temperatures while minimizing thermal stress on equipment, thereby significantly extending the lifecycle of critical assets.

One of the standout technical features of the Applied Materials SINGLE COOLDOWN CHAMBER is its high input/output capacity. It supports a wide range of thermal loads and can handle rapid temperature transitions with exceptional accuracy. The chamber’s durability is reinforced by corrosion-resistant alloys and precision-engineered seals, making it highly reliable even under continuous operation in harsh industrial conditions. Performance metrics highlight its ability to achieve cooldown cycles efficiently within minimal timeframes, often outperforming similar solutions in the market. This fast and consistent cooldown capability reduces downtime and increases throughput, crucial factors in high-volume applications.

In real-world applications, the SINGLE COOLDOWN CHAMBER shines in scenarios where thermal cycling and temperature control are critical. In the power industry, it supports the cooldown of turbine components and power generation instrumentation, ensuring rapid readiness and reducing the risk of thermal fatigue. Within petrochemical plants, the chamber aids in the controlled cooling of reactors and heat exchangers following high-temperature processes, safeguarding against material deformation and maintaining safety standards. Its adaptability also allows seamless integration into general automation workflows, where precise temperature regulation enhances the performance of automated assembly lines and testing stations.

When compared with other Applied Materials models, the SINGLE COOLDOWN CHAMBER offers unique advantages. Unlike the Applied Materials 0010-10901 and Applied Materials 0010-26439, which focus primarily on temperature measurement and control modules, the SINGLE COOLDOWN CHAMBER delivers comprehensive thermal management with integrated cooldown functionality. Compared to Applied Materials 0190-49615 and Applied Materials 0041-35140, which serve as subsystem components within larger equipment setups, the SINGLE COOLDOWN CHAMBER functions as a standalone unit capable of both rapid cooldown and continuous operation. This versatility makes it highly suitable for both retrofit and new installations.

Alongside the Applied Materials SINGLE COOLDOWN CHAMBER, we also offer complementary models such as the Applied Materials 0100-35218 and Applied Materials 0190-35864, which provide advanced temperature sensing and control interfaces, facilitating seamless integration into complex control systems. The Applied Materials 0010-22225 and Applied Materials 0041-05925 models serve as excellent partners for automation framework management, enhancing system reliability and data acquisition. For applications requiring enhanced environmental protection, the Applied Materials 0190-09454 and Applied Materials 0010-23684 REV 003 offer ruggedized enclosures and filtration modules. Additionally, the Applied Materials 0020-34338 and Applied Materials 0227-34347 provide power regulation and distribution features that perfectly complement the cooldown chamber’s operational needs.

Incorporating the Applied Materials SINGLE COOLDOWN CHAMBER into your industrial processes guarantees not only technical excellence but also a significant boost in operational efficiency. Its robust design and superior cooldown performance make it an indispensable asset in the application of SINGLE COOLDOWN CHAMBER in power industry, petrochemical, and general automation contexts. This product stands as a testament to Applied Materials’ commitment to delivering cutting-edge automation products engineered for reliability and precision.

For enterprises seeking to optimize thermal management while reducing downtime and maintenance costs, the Applied Materials SINGLE COOLDOWN CHAMBER offers a proven and scalable solution. Supported by a comprehensive ecosystem of Applied Materials automation products, including the aforementioned models, it ensures a holistic approach to process control and equipment longevity. Whether upgrading existing systems or deploying new automation lines, the SINGLE COOLDOWN CHAMBER represents a forward-thinking investment in industrial excellence.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923