K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Current position:

Brand

Description

Introducing the ABB IRB 2600: A New Standard in Industrial Robotics

ABB IRB 2600 - Modular Robots Series, Comprehensive Control Solution

ABB IRB 2600 - Modular Robots Series, Comprehensive Control Solution

Introducing the ABB IRB 2600: A New Standard in Industrial Robotics

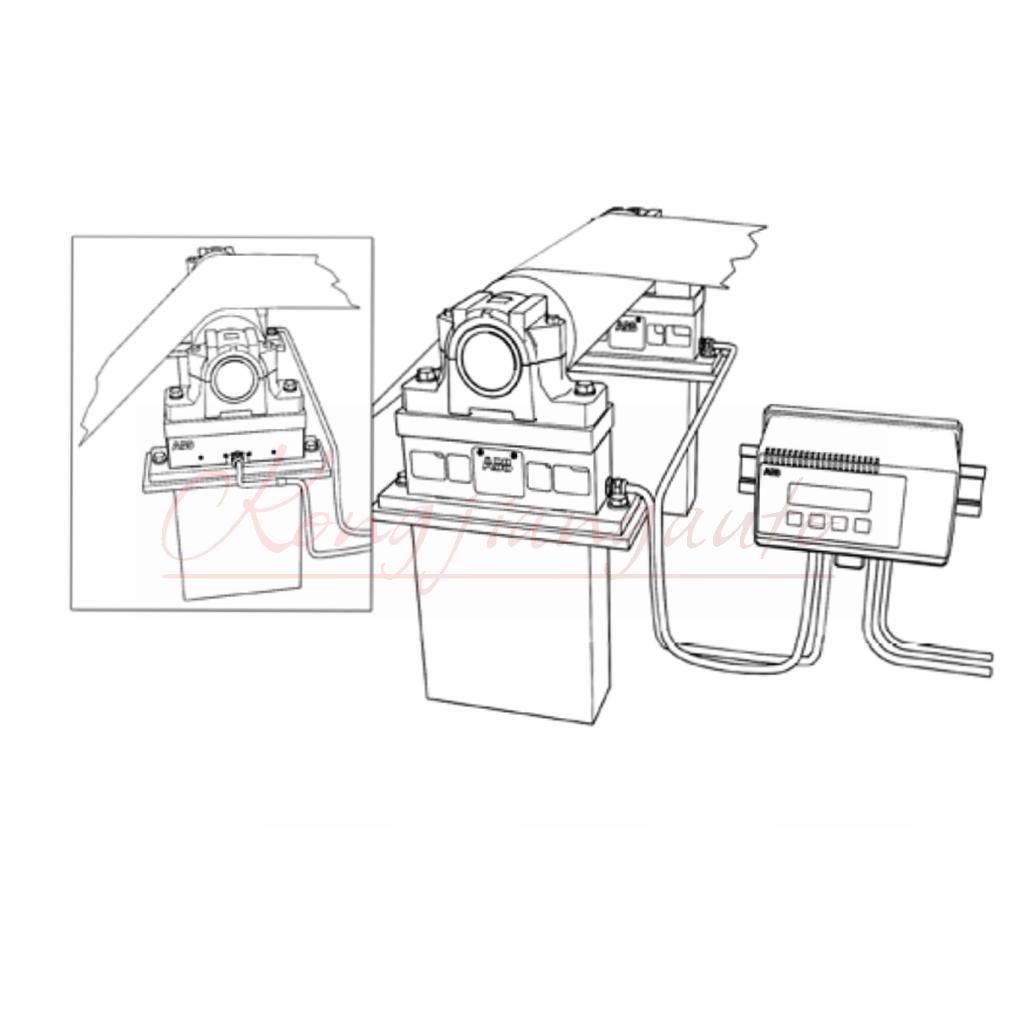

The ABB IRB 2600 is a compact, versatile industrial robot that sets a new benchmark in automation technology. Designed to meet the demands of modern manufacturing environments, this robot combines precision, speed, and reliability to enhance productivity across various applications. As part of ABB’s comprehensive range of automation products, the IRB 2600 seamlessly integrates into diverse workflows, making it an essential asset for businesses looking to elevate their operational efficiency.

Key Technical Features

The ABB IRB 2600 boasts a variety of impressive technical specifications that cater to both small and large-scale manufacturing processes. Its key features include:

1. **Payload Capacity**: With a maximum payload of up to 20 kilograms, the IRB 2600 is engineered to handle a wide range of materials and components, making it suitable for tasks such as assembly, packaging, and material handling.

2. **Reach and Flexibility**: The robot offers a reach of up to 1.65 meters, providing flexibility for various applications. Its compact design allows it to operate in confined spaces while maintaining a high degree of precision.

3. **Speed and Efficiency**: The ABB IRB 2600 is designed for speed, achieving cycle times that are among the best in its class. This high-performance capability enables quicker production cycles, ultimately leading to increased output.

4. **Advanced Control Technology**: Equipped with ABB’s latest control technology, the IRB 2600 offers intuitive programming and operation. It can be easily integrated with existing systems, ensuring a smooth transition to automation.

5. **Durability and Reliability**: Built to withstand the rigors of industrial environments, the IRB 2600 features robust construction and is resistant to dust and splashes, making it ideal for a variety of applications.

Usage Scenarios

The ABB IRB 2600 is incredibly versatile, making it suitable for a range of applications across different industries. Here are some common usage scenarios:

1. **Automotive Manufacturing**: In the automotive sector, the IRB 2600 can be employed for tasks such as welding, painting, and assembly, improving efficiency and ensuring high-quality results.

2. **Electronics Assembly**: This robot is perfect for delicate electronic components, providing precise handling and assembly capabilities that minimize the risk of damage.

3. **Food and Beverage Industry**: With its hygienic design, the IRB 2600 can be utilized for packaging, sorting, and palletizing in food production, enhancing safety and efficiency.

4. **Pharmaceuticals**: The robot’s precise movement and speed make it ideal for pharmaceutical assembly lines where accuracy is paramount.

5. **General Manufacturing**: Whether it’s material handling, machine tending, or quality inspection, the ABB IRB 2600 excels in various manufacturing scenarios, ensuring increased productivity across the board.

Comparison with Other Models

When comparing the ABB IRB 2600 to other models within the ABB automation products lineup, it stands out for its balanced combination of payload capacity, reach, and speed. For instance, the ABB IRB 2400, while also a popular choice, offers a slightly higher payload but at the expense of reach. In contrast, the IRB 2600 is designed to provide optimal performance in tighter spaces without compromising on speed.

Another notable comparison is with the ABB IRB 6700, which boasts a larger payload and reach but is not as compact as the IRB 2600. This makes the IRB 2600 an ideal choice for smaller facilities or operations where space is a concern. Additionally, the IRB 2600’s advanced control technology provides an edge in ease of programming and integration with existing systems compared to older models like the ABB 07DC91.

Reference to Related Models

As part of ABB’s extensive range of industrial robots and automation solutions, the IRB 2600 aligns with several related models that cater to specific needs in automation:

1. **ABB IRB 2400**: Known for its versatility in manufacturing applications, this model is often used in welding and material handling tasks.

2. **ABB IRB 6700**: A heavy-duty robot that excels in high-payload applications, particularly in automotive and heavy manufacturing sectors.

3. **ABB IRB 140**: A compact robot ideal for small parts assembly and intricate tasks in limited spaces.

4. **ABB IRB 6600**: Provides a higher payload capacity, suited for heavy-duty applications and larger components.

5. **ABB IRB 6700**: Another robust option for heavy lifting and complex assembly processes.

6. **ABB IRB 5400**: A flexible robot designed for various applications, including packaging and palletizing.

7. **ABB IRB 6700**: Known for its extensive reach and flexibility, ideal for larger work areas.

8. **ABB IRB 8800**: Designed for applications requiring high precision and speed, particularly in the automotive sector.

9. **ABB IRB 6700**: A versatile option suitable for large-scale manufacturing, offering a robust payload capacity.

10. **ABB IRB 7600**: Tailored for high-speed applications, providing efficiency and accuracy in production lines.

In Conclusion

The ABB IRB 2600 is a game-changer in the realm of industrial automation. With its remarkable technical features, versatile usage scenarios, and competitive edge over other models, this robot is an ideal solution for businesses looking to optimize their manufacturing processes. By choosing the IRB 2600, you’re not just investing in a robot; you’re investing in the future of your operations with ABB automation products. Enhance your productivity, precision, and profitability with the ABB IRB 2600—where innovation meets efficiency.

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Customer Reviews

Satisfaction :

5 Stars

No evaluation information

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923