K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Current position:

Brand

Description

**ABB IRB4600: Precision and Versatility in Automation**

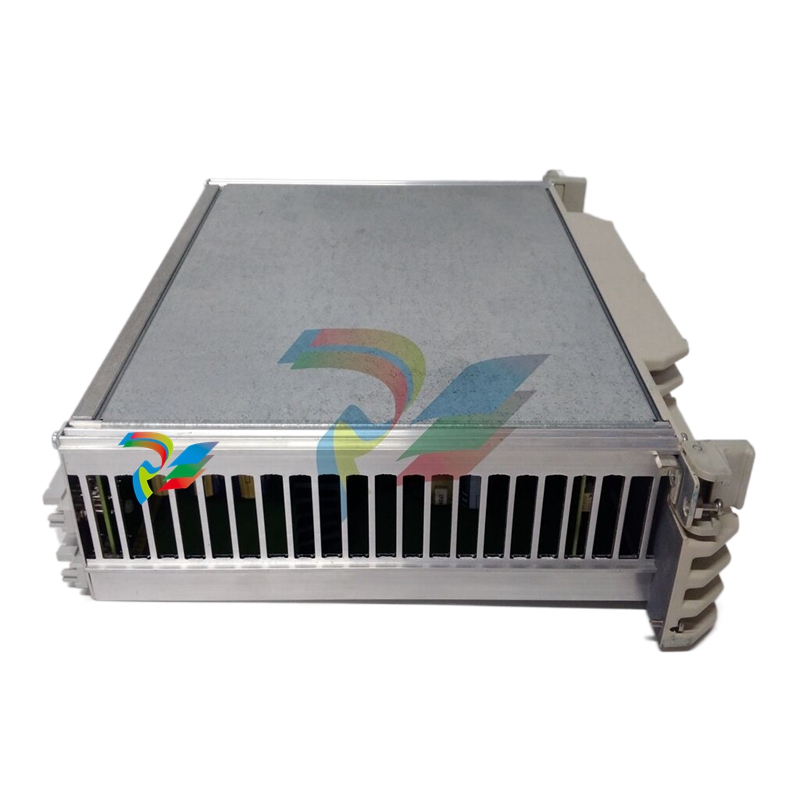

ABB IRB4600 - 3HAC2493-1/2/8/9/10/11 Series Manipulators, Advanced Industrial Robots

ABB IRB4600 - 3HAC2493-1/2/8/9/10/11 Series Manipulators, Advanced Industrial Robots

**ABB IRB4600: Precision and Versatility in Automation**

The ABB IRB4600 is a state-of-the-art industrial robot designed to excel in power, petrochemical, and general automation applications. This model stands out with its remarkable blend of speed, precision, and robustness, making it an indispensable asset in modern production environments.

One of the key technical features of the ABB IRB4600 is its impressive payload capacity, which allows for handling loads up to 60 kg. Its reach of 1.55 to 2.0 meters enables it to cover a wider working area without compromising on performance. The IRB4600 is engineered for superior durability, featuring a rigid design that ensures longevity even in the most demanding environments. With a repeatability of ±0.05 mm and optimized servo performance, the IRB4600 guarantees precision in tasks ranging from material handling to assembly and welding.

In terms of input/output capacity, the ABB IRB4600 offers extensive integration capabilities. It supports a variety of communication protocols, making it compatible with other ABB automation products such as the ABB DI810 Digital Input Module for 24V DC, 16 Channels, ensuring seamless connectivity. This versatility enhances the robot's ability to be easily integrated into existing systems, facilitating a smooth transition to advanced automation solutions.

Real-world usage scenarios highlight the ABB IRB4600’s exceptional performance in various sectors. In the power industry, it can efficiently handle heavy components and perform intricate assembly tasks, thereby reducing downtime and increasing throughput. In the petrochemical sector, the robot's robustness and precision make it ideal for tasks like welding and material handling, where safety and accuracy are paramount. Moreover, in general automation, the IRB4600 excels in repetitive tasks, ensuring consistent quality and efficiency.

When compared to other models within the ABB lineup, such as the ABB DI650 or the ABB ACSM1-04AM-09A5-4+L517 SERVO DRIVER, the IRB4600 offers unique advantages in terms of payload and reach. While the ABB DI650 is tailored more for digital input tasks, the IRB4600's versatility allows it to take on a wider range of functions. Similarly, while the ABB ACSM1 series focuses on drive control, the IRB4600 operates seamlessly alongside these units, enhancing overall system performance.

The ABB IRB4600 can be complemented by several related models from ABB's extensive catalog. For instance, integrating it with the ABB PFTA102 Control Unit can enhance operational efficiency, while the ABB 3HAC025488-001 provides advanced control features that are essential for complex automation tasks. The robot can also work in conjunction with the ABB 3BHE024820R0101 PPD234 A101 Module Card for enhanced monitoring and control capabilities.

Furthermore, the ABB SDCS-POW-1 and ABB GJR offer power management solutions that ensure the IRB4600 operates optimally within its parameters, while the ABB DI810-EA 3BSE008508R2 serves as an advanced input module, facilitating real-time data processing. The ABB 3BHB003387R0101 | 3BHL000385P0101 | 5SHX0845F0001 series can be integrated for significant improvements in system diagnostics and monitoring.

In summary, the ABB IRB4600 is a top-tier choice for industries looking to enhance their automation capabilities. With its superior payload capacity, precision, and compatibility with other ABB automation products, including the ABB DI650 and ABB ACSM1-04AM-09A5-4+L517, it is expertly designed for the power industry, petrochemical applications, and general automation. By choosing the ABB IRB4600, businesses can look forward to increased efficiency, reliability, and innovation in their automation processes.

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Customer Reviews

Satisfaction :

5 Stars

No evaluation information

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923