K-WANG

Honeywell FC-SCNT02 - 51460114-176 S300 Controller Module 78-4

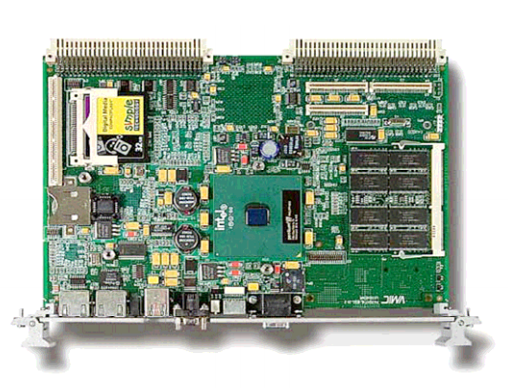

The Honeywell FC-SCNT02 is a robust and highly reliable automation controller designed specifically for demanding applications in the power industry, petrochemical sectors, and general automation environments. Engineered for precision and durability, the FC-SCNT02 stands out with its exceptional input/output (I/O) capacity, high-performance processing capabilities, and rugged construction to withstand harsh industrial conditions.

At its core, the Honeywell FC-SCNT02 features a versatile I/O system capable of handling up to 128 digital and analog inputs and outputs. This extensive capacity supports complex control schemes and data acquisition needs, providing flexibility for diverse automation tasks. The controller operates with a high-speed processor optimized for rapid data processing and real-time control, ensuring minimal latency and maximum system responsiveness. Its robust hardware design incorporates industrial-grade components, granting superior resistance against temperature extremes, vibration, and electromagnetic interference, which are common challenges in power plants and petrochemical facilities.

Performance-wise, the FC-SCNT02 delivers reliable operation with a mean time between failures (MTBF) exceeding industry standards, ensuring continuous uptime in critical applications. The controller supports multiple communication protocols, including Modbus, Profibus, and Ethernet/IP, enabling seamless integration into existing Honeywell automation networks or third-party systems. Moreover, its onboard diagnostics and self-monitoring features simplify maintenance, reducing downtime and operational costs.

In real-world scenarios, the Honeywell FC-SCNT02 excels in applications requiring precise control and monitoring across complex processes. In the power industry, it manages generator synchronization, load sharing, and real-time fault detection, ensuring power plant stability and safety. Within petrochemical plants, the controller oversees critical parameters such as pressure, temperature, and flow rates, contributing to optimized production and risk mitigation. For general automation, the FC-SCNT02 efficiently coordinates machinery operation, conveyor systems, and batch processing, enhancing productivity and operational efficiency.

When compared to other Honeywell automation products, the FC-SCNT02 offers distinct advantages. Unlike the Honeywell W7752D-2007, which is primarily focused on smaller-scale control, the FC-SCNT02 supports a broader range of I/O and higher processing speeds, making it ideal for complex industrial environments. Compared to the Honeywell ED600, which serves as an environmental data logger, the FC-SCNT02 provides more comprehensive control functionalities with extensive communication capabilities. Additionally, while the Honeywell WEB-600E excels as an embedded web server for remote monitoring, the FC-SCNT02 integrates full control and monitoring in a single unit, simplifying system architecture.

Alongside the Honeywell FC-SCNT02, complementary products such as the Honeywell 620-0073 input/output modules and the Honeywell 1616-350-01A relay boards enhance system scalability and customization. For advanced networking and interface needs, the Honeywell JACE-512-UI and Honeywell CC-IP0101 network controllers provide seamless connectivity options. The Honeywell TSQUALWDX-07821 sensor modules and Honeywell DMU data management units further expand the system’s data acquisition and processing capabilities. Moreover, the Honeywell 098067-01 power supplies ensure stable and reliable energy delivery to the FC-SCNT02 and associated components.

In terms of application, the Honeywell FC-SCNT02 is the go-to solution in sectors requiring rigorous automation standards. Its extensive I/O capacity, rugged durability, and high-speed processing make it indispensable in the power industry for turbine control and energy distribution management. The petrochemical sector benefits from its precise regulatory functions that handle critical safety parameters and process optimization. In general automation, the FC-SCNT02’s flexible architecture supports everything from assembly line coordination to complex batch processing systems.

The Honeywell FC-SCNT02’s combination of advanced technical features, proven reliability, and versatile application range positions it as a leading product in Honeywell automation products. It is designed to meet the evolving needs of industries where performance, accuracy, and dependability are paramount. Whether integrated with Honeywell’s 80363975-150 interface modules or paired with the Honeywell RCZ851E safety controllers, the FC-SCNT02 enhances operational efficiency and ensures robust process control.

For organizations seeking an automation controller that offers exceptional I/O capacity, ruggedness, and seamless integration, the Honeywell FC-SCNT02 represents a sound investment. Its proven track record in power industry, petrochemical, and general automation applications underscores its capability to handle complex control challenges reliably. With the support of Honeywell’s broad product ecosystem—including the Honeywell WEB-8200-U visualization units and Honeywell TSENALMOX-08287 sensor arrays—the FC-SCNT02 provides a comprehensive solution tailored to modern industrial automation demands.

In summary, the Honeywell FC-SCNT02 combines high performance, durability, and versatility, making it an essential component for advanced industrial automation systems. Its application in the power industry, petrochemical processing, and general automation continues to drive operational excellence, supported by Honeywell’s extensive range of complementary products and proven technological expertise

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923