K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Brand

Product parameters

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Description

When configuring a VersaMax IP the following guidelines should be considered

1. Remember to select the proper cord set and termination resistor

2. VersaMax IP Modular can support up to 16 Modular expansions with a total expansion length of 20 meters

GE IC695PSA040 Industrial I/O

Industrial I/OConfiguration Guidelines

When configuring a VersaMax IP the following guidelines should be considered

1. Remember to select the proper cord set and termination resistor

2. VersaMax IP Modular can support up to 16 Modular expansions with a total expansion length of 20 meters

Examples of Typical Application

Configuration for Controller (Example application requiring (120) 24VDC inputs and (80) Relay outputs AC power supply) for local control. System also has five remote

drops that will be mounted external to the machine. Each remote drop requires (8) 24VDC Inputs, (4) 24VDC 0.5 Amp, Source Outputs and (2) current inputs and (2) current outputs

(24VDC power source) over Profibus DP.

Control Cabinet

Backplane Slots

Required

Power Supply

Current Required (mA)

Qty Part Number Description

2 1250 mA @ 3.3 VDC; 1000mA @ 5 VDC 1 IC695CPU310 CPU with two built-in serial ports

2 1 IC695PSA040 120/240 VAC, 125 VDC Power Supply, current available

9 Amps @ 3.3 VDC; 6 Amps @ 5 VDC; 1.6 Amps @ 24 VDC maximum

600 mA @ 3.3 VDC; 240 mA @ 5 VDC 1 IC695CHS016 16 Slot Universal Base

4 1200 mA @ 5V 4 IC694MDL660 Discrete Input Module, 24 VDC Positive Logic, 32 points

(Requires terminal block)

5 35 mA @ 5V; 110mA @ 24 VDC Relay 5 IC694MDL940 Discrete Output Module, Relay 2.0 A per point Form A, 16 points

(Terminal block included).

4 IC694TBB032 Terminal Block, Box Style

1 420 mA @ 5 VDC 1 IC695PBM300 Profibus DP Master Module

1 BC646MPP001 Logic Developer -PLC Professional

14 Total current from power supply required: 2895mA @ 5V; 1850 @ 3.3V; 110mA @ 24 VDC Relay. Only one power supplied needed.

Remote Cabinets (Qty 5)

5 IC677PBI001 Profibus VersaMax IP Modular local bus master with (8) 24 VDC inputs

5 IC677DBO085 Expansion VersaMax IP Modular slave with (8) 24 VDC outputs

5 IC677ABI004 Expansion VersaMax IP Modular slave with (4) analog inputs

5 IC677ABO004 Expansion VersaMax IP Modular slave with (4) analog outputs

5 IC676CBLPBB100 IP67 Profibus Cordset -10 Meters

5 IC676CBLPWB100 IP67 Power Cordset -10 Meters

15 IC677CBLPWB0013 IP67 Voltage supply cable for local bus; A-coded, 5 position,

unshielded 13.5 cm.

15 IC677CBLLBB0013 IP67 Local communications cable for local bus; B-coded, 5 position,

shielded 13.5 cm.

Options to Consider

840mA @ 3.3 VDC; 614 mA @ 5 VDC 1 IC695ETM001 RX3i Ethernet module 10/100 Mbits 2 RJ45 connections one

IP address occupies one slot on system base

6 IC690PWR024 24 VDC, 5 Amp Output Power and 120/230 VAC Input Power Power Supply

1 IC693ACC302 RX3i Long term battery for CPU

1 IC754VSI06STD QuickPanel View Intermediate 6 inch STN Touch Operator Interface

RSTi

The new RSTi I/O system is Profinet enabled and ideal for distributed control applications. The compact, granular “build as you

go” design of the RSTi enables the user to optimize the design of the system and therefore minimize cost.

The RSTi is also Network Independent with over 10 different bus interfaces available such as Profibus, Modbus (serial and

Ethernet), EthernetIP, EtherCAT, CANopen, and CCLink. The RSTi is supported by over 80 discrete, analog, motion and specialty

I/O modules to address simple to complex applications.

Benefits of RSTi

• Network Independence: OEMs and

System Integrators can standardize

on their I/O layout without worrying

about the controller it is connected

to.

• Reduced Development Time:

Panels can be fabricated in advance,

independent of the control system, by

simply changing out the network/bus

interface without impact to wiring.

• Reduced Installation Cost:

Distributed I/O networks reduce

installation and wiring cost.

• Lower Cost Per Point: The RSTi can

be configured to meet application

needs. The granular design reduces

panel space and module cost.

• “Build as You Go”: Expansion is

simple; just slide in a RSTi I/O module

without impacting the wiring back to

the main control panel.

• System Simplification: The

distributed nature of the RSTi greatly

reduces the time to dis-assemble and

re-assemble a machine, therefore

reducing machine commissioning.

Publication Reference Chart

GFK-2745 RSTi I/O User Manual

GFK-2746 RSTi Network Adapter Manual

The RSTi is ideal for distributed I/O systems with as a few 4 I/O per location or

hundreds of I/O.

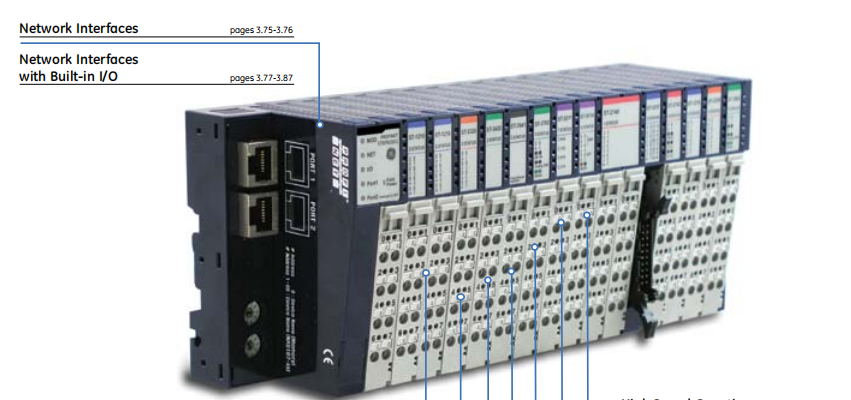

Network Interfaces pages 3.75-3.76

Network Interfaces

with Built-in I/O pages 3.77-3.87

Discrete I/O Modules (Input) pages 3.88-3.90

Discrete I/O Modules (Output) pages 3.94-3.98

Analog I/O Modules (Input) pages 3.91-3.93

Analog I/O Modules (Output) pages 3.99-3.101

High Speed Counting pages 3.106-3.107

Serial Communications Modules pages 3.104-3.105

RTD Modules page 3.102

Power Modules pages 3.110-3.112

Thermocouple Modules page 3.103

Motion Control pages 3.108-3.109

Expansion Modules page 3.113

Configuration Tools pages 3.114-3.115

Accessories page 3.116

Typical Application page 3.117

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Related products

Customer Reviews

Satisfaction :

5 Stars

No evaluation information

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923