K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Brand

Product parameters

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Description

FAU810 Specifications

Each Flame Analysis Unit consists of two independent

channels. Each channel can receive and process a Flame

Detector signal. The two Detectors may be in any combination

of the following designs:

− SF810 Flame scanner heads

− All DFS Flame scanner heads

− Flame Rods (Ionic Flame Monitoring)

ABB FAU810 Flame Analysis Unit

Flexible and Reliable Device for use with all ABB FlameDetectors.

The Flame Analysis Unit, or FAU810, is ABB’s latest

leading-edge fl ame analysis device.

The FAU810 is designed from the ground up for maximum

fl exibility, usability and reliability. It takes advantage of the

latest technologies available to make fl ame analysis as

cost-effi cient as possible, while retaining ABB’s rock-solid

reputation as the most reliable instruments in the industry.

The FAU810 is easy to install and confi gure, fl exible to

operate, and uses redundant Profi bus DP-V1 or standard

Modbus interfaces for easy and safe data exchange and

tuning. You can connect any type of ABB Flame sensing

device to the FAU810. This makes the FAU810 the standard

module for all ABB Flame Scanner application and the

preferred solution for retrofi tting existing installation.

It determines if the current signal value is within the

programmed limits as defi ned by Functions. A variety of

limits can be defi ned in the FAU810 to account for any

situation that may occur in utility or industrial boilers.

Collects Signal Values from the Flame Detector

The FAU810 analyzes the signals generated from the Flame

Detector.

Calculates Signal Quality

The FAU810 measures the quality of the signal to provide an

indication of changes in the burner flame.

Quality values act as a barometer, forecasting when a burner

flame-out is likely to occur. This can help you to anticipate

changes and problems.

Continuously Detect Faults

The instrument automatically monitors the electronic

components of the Flame Detector and FAU810 unit to detect

system problems or faults.

Signals Unsafe Conditions

A no-flame condition occurs when the FAU810 logic

determines that an unsafe condition exists.

Remote supervisory

Extended set-up, parameter fi les archiving, groups view,

advanced diagnostic including fl ame raw data, real time and

historical trends of up to 254 scanner heads networked is

possible either through the PC based package Flame ExplorerTM

or with DTM through any Profi bus DP-V1 master remote.

FAU810 Specifications

Each Flame Analysis Unit consists of two independent

channels. Each channel can receive and process a Flame

Detector signal. The two Detectors may be in any combination

of the following designs:

− SF810 Flame scanner heads

− All DFS Flame scanner heads

− Flame Rods (Ionic Flame Monitoring)

Each Detector is independently configurable from the FAU810

pushbuttons and display, with Flame Explorer engineering tool

or via Profibus

The FAU810 can be powered by a single or redundant 24

VDC source (+/- 20%).

The FAU810 has built-in diode auctioneering for power source

isolation.

Two digital input channels are available for remote parameter

switching. One digital input per sensor.

(Example: Parameters for a dedicated Flame Detector may be

tailored to monitor either coal or oil firing)

The FAU810 can be upgraded on site with any official

release of new product features by the proprietary Firmware

Download Utility.

FAU810 Specifications

Flame Failure Relay Drop-Out Configurable 0.2 to 4 seconds

Flame Relay(s) Three total, each with Form C contacts

Flame Relay Contact Ratings 250 Vac, 3A, 750 VA; 220Vdc, 300 ma, 66 watts

Fault Relay Contact Ratings 250 Vac, 3A, 750 VA; 220Vdc, 300 ma, 66 watts

Analog Flame Signal Outputs Two channels of 4-20 ma signals. Each channel may independently monitor Intensity, Frequency, Quality, or AC Amplitude

Serial Data Communication Two Galvanically isolated RS-485 interfaces (fully independent for redundancy)

Serial Data Format MODBUS (default), PROFIBUS DP-V1 (selectable)

Self Checking Time Cycle Electronics shall be checked every 0.1 seconds

Ambient Temperature 0° to 60° C (32°F to 140°F), 95% non-condensing atmosphere

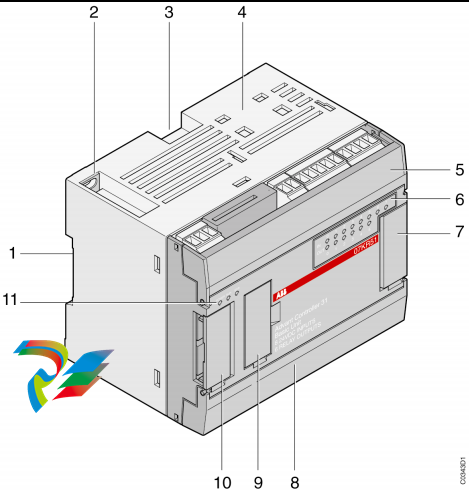

Case Dimensions 13 cm height, 12 cm long, 11 cm wide

Electrical Connections Screw terminals, compression type, accepting 12 to 20 wire gage

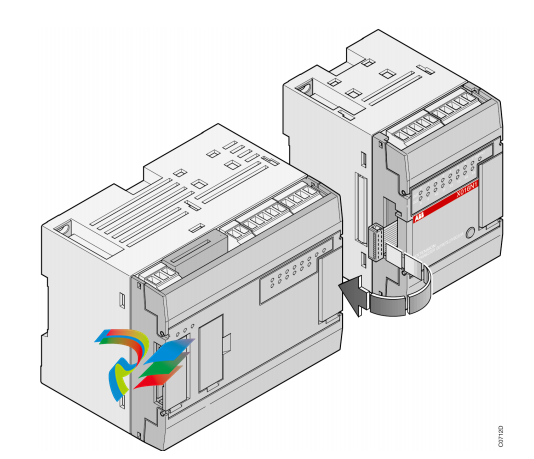

Module Mounting Din Rail Mounted

Power Consumption: 4 watts Minimum, 10 watts Maximum, Typical 6 watts

Stacking Limitation 4 modules with power entry on the end module or 7 modules with power entry on the middle module

Power supply voltage 24VDC (-25%, +20% = 18 ÷ 29VDC )

Inrush current 6A peak, 2ms settling time

Customer Interface Specifications

LCD Display Graphic LCD Display Module displaying 4 lines of 20 characters and multiple bar graphs

Programming Push-Buttons 4 (Program, Display, Up, and Down)

Status Lights 4 (Power, Flame #1, Flame #2, and Flame #3 or Fault)

Program Lock-Out Local, DIP switch select

Flame/No Flame Bypass Key None on board

Remote Programming Remote programming of functions via RS-485 link and Flame Explorer software

RS 485 2 RS-485 interfaces, one for each channel for redundancy (each interface has access to both channels)

Relay Outputs 3 – Flame #1, Flame #2, and Flame #3 or Fault

Analog Outputs Two 4-20 ma analog outputs for Trending or Monitoring of Frequency, Intensity, Quality, or AC Amplitude

4÷20 mA (R load <= 500Ω) Galvanically isolated Precision: +/-5% f.s.

Module Set-Up Menus Module Set-Up is divided into two menus, “Configuration” and ”Program”. Edit mode is protected against

occasional mistyping

Recommended ABB standard

cable:

Single Sensor scanner P/N EC-DWG-G041ELE803

Dual Sensor scanner P/N EC-DWG-GO41ELE802

Maximum distance between SF810 scanner and FAU810, Flame Analysis Unit 500 meters (1500 feet)

Compatible scanner Refer to the table below for the compatibility of the FAU810 with the associated flame scannerOrdering code C10-12010 “FAU810 - Flame Analysis Unit, Dual Channel Complete Assembly with Dual Profibus DPV1”

Scanner Models Analysis Units

DFS FAU800 FAU810

SF810-IR Series (=/> Rev.E) XXX

SF810-IR Series (< Rev.E) XXX

SF810-UV Series (=/> Rev.E) X

SF810-UV Series (< Rev.E) XXX

SF810-UVIR Series (=/> Rev.E) X

SF810-UVIR Series (< Rev.E) X X

SF810-VL Series (=/> Rev.E) XXX

SF810-VL Series (< Rev.E) XXX

Safe Flame VL assembly round board (C10-24112) XXX

Safe FlameIR assembly round board (C10-24113) XXX

Safe Flame Full Spectrum assembly round board (C10-24114) XXX

1.5 Deg. PC board (C87-97308) XXX

4 Deg. PC board (C87-97342) XXX

IFM (Ionization Flame Rod) X X

Quick connect pin SF810 UVIR Term. Board Signal Name Internal wiring colour Pig tail fly end label Functional description

F 1 +15V Gr/Cy A (+B) Power supply +15V from FAU810/DFS

G 2 -15V Ye/Re B (-B) Power supply -15V from FAU810/DFS

H 3 IR SIG Ye/Bl C (SIG.IR) Live flame signal IR

J 4 GND Ye/Br D (Comm) Power supply return

Ground reference

E Not used

A 6 +15V Gr/Or F (+B) Power supply +15V from FAU810/DFS

B 7 -15V Gr/Mg G (-B) Power supply -15V from FAU810/DFS

C 8 UV SIG Gr/Bl H (SIG.UV) Live flame signal UV

D 9 GND Gr/Bk J (Comm) Power supply return

Ground reference

K Not used

L Not used

M 5 Wt/Re Not used

N 10 Wt/Bk Not used

P Not used

R Not used

S Not used

T Shield Grey T (Sh) Cable screen grounding

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Related products

Customer Reviews

Satisfaction :

5 Stars

No evaluation information

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923