K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Brand

Product parameters

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Description

The IRB 910SC (SCARA) is fast,

cost-effective and, because it‘s

from ABB, accurate. In designing its

Selective Compliance Articulated

Robot Arm (SCARA), or IRB 910SC,

ABB has delivered a single arm robot

capable of operating in a confined

footprint. ABB’s SCARA is ideal for

the Small Parts Assembly, Material

Handling and parts inspection.

ABB IRB910SC SCARA

The IRB 910SC (SCARA) is fast,cost-effective and, because it‘s

from ABB, accurate. In designing its

Selective Compliance Articulated

Robot Arm (SCARA), or IRB 910SC,

ABB has delivered a single arm robot

capable of operating in a confined

footprint. ABB’s SCARA is ideal for

the Small Parts Assembly, Material

Handling and parts inspection

Variants

With a maximum payload of 6 kg, the IRB 910SC is

available in three configurations (IRB 910SC –3/0.45,

IRB 910SC – 3/0.55m, and IRB 910SC – 3/0.65.).

All are modular by design, with different linking arm

lengths and have individual reaches of 450 mm,

550 mm and 650 mm, respectively.

All members of the SCARA family are tabletop

mountable.

Applications

ABB’s SCARA family is designed for a variety of

general-purpose applications such as tray kitting,

component placement, machine loading/unloading

and assembly.

These applications require fast, repeatable and

articulate point-to-point movements such as pallet izing, depalletizing, machine loading/unloading and

assembly.

ABB’s SCARA family is ideal for customers requiring

rapid cycle times, high precision and high reliability

for their Small Part Assembly applications and for

laboratory automation and prescription drug

dispensing.

Features

• Table top mountable

• Ease of integration

• Custom interfaces

• Modular design

Customer benefits

• Short cycle times which achieved by high speed

• High precision which is achieved by superior

motion control

• Superb reliability due to reuse and standard

proven components.

Specification

Robot version

Reach

Payload (kg)*

(m)

IRB 910SC-3/0.45

0.45

Rated:3,Max:6

IRB 910SC-3/0.55

0.55

Rated:3,Max: 6

IRB 910SC-3/0.65

0.65

Rated: 3,Max: 6

Number of axes

4

Protection

IP20

Mounting

Table

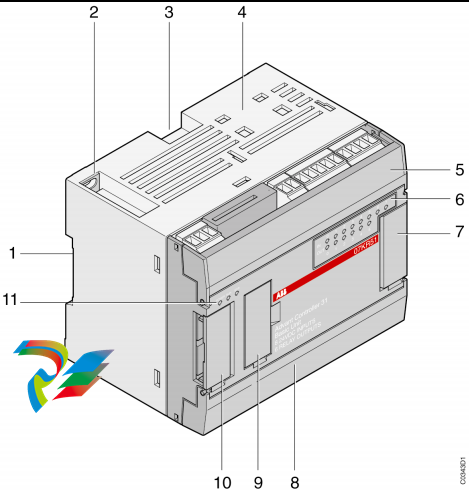

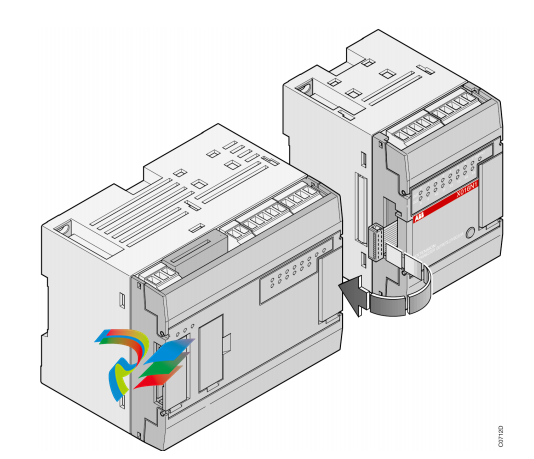

Controller

IRC5 Compact

Integrated signal

10 signals on wrist

Integrated air supply

4 air on wrist (5 bar)

*Armload is included in the max paylead.

Performance (according to lSO 9283)

Robot version

IRB 910SC IRB 910SC IRB 910SC

-3/0.45

-3/0.55

-3/0.65

1 kg picking cycle

0.380 s

0.370s

0.385s

Max TCPVelocity

6.2m/s

6.9m/s

7.6m/s

Max TCPAcceleration

65 m/s

60 m/s

55 m/s

Acceleration time 0-1m/s

0.04 s

0.05s

0.06s

Axis 3 (Z stroke) down force 250 N

250 N

250N

Position repeatability

Axis 1+Axis 2 (mm)

±0.015

±0.015

±0.015

Axis 3 (mm)

±0.01

±0.01

±0.01

Axis4(*)

±0.005

±0.005

±0.005

Technicalinformation

Electrical Connections

Supply voltage

200-600V,50/60Hz

Transformer rating

3.0 kVA

Power consumption

220W

Physical

Footprint

160 x160 mm

Weight IRB 910SC-3/0.45

24.5kg

Weight IRB 910SC-3/0.55

25kg

Weight IRB 910SC-3/0.65

25.5kg

Environment

Ambient temperature for mechanicalunit

Manipulator during operation + 5*C (41*F) to + 45*C(113*F)

Complete robot during

-25*℃(-13*F) to +55*C(131*F)

transportation and storage

For short periods (not

up to + 70℃ (158*F)

exceeding 24 hours)

Relative humidity

Max.95% at constant temperature

Noise level

<70dB

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Related products

Customer Reviews

Satisfaction :

5 Stars

No evaluation information

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923