K-WANG

Applied Materials 0040-86650 REV. 003 - AMAT RF COIL FOR ETCH CHMABER

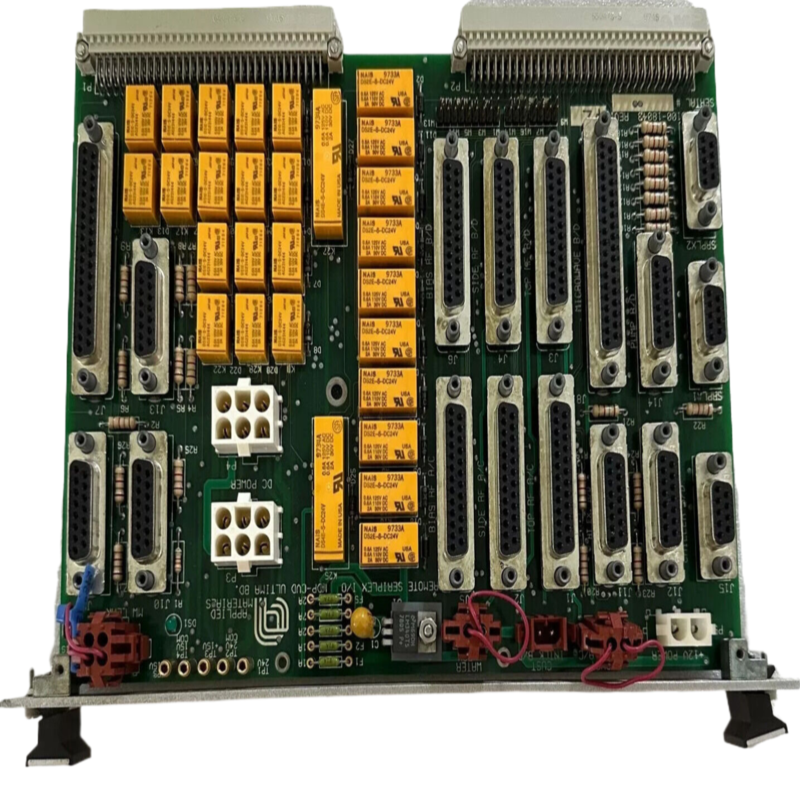

The Applied Materials 0040-86650 REV. 003 stands as a robust and versatile solution specifically engineered to meet the rigorous demands of the power industry, petrochemical sector, and general automation environments. This model is distinguished by its exceptional input/output capacity, delivering seamless communication between complex control systems and critical industrial equipment. Designed for high durability, the 0040-86650 REV. 003 features reinforced circuitry and advanced thermal management, ensuring long-term operational stability even under extreme environmental conditions commonly found in heavy industrial applications.

Key technical features of the Applied Materials 0040-86650 REV. 003 include a high-density I/O configuration capable of handling up to 256 discrete inputs and outputs, supporting both analog and digital signals with minimal latency. This ensures real-time responsiveness critical in automation workflows where precision and timing are paramount. The unit incorporates enhanced electromagnetic interference (EMI) shielding, reducing signal degradation in electrically noisy environments typical of petrochemical plants and power generation facilities. The model also supports multiple communication protocols, offering flexibility for integration with legacy systems as well as modern SCADA architectures. Its rugged enclosure provides IP65-rated protection, safeguarding internal components from dust, moisture, and corrosive agents.

In real-world scenarios, the Applied Materials 0040-86650 REV. 003 excels in automating power grid substations, where reliable switching and monitoring of transformers and circuit breakers are essential. It is equally effective in petrochemical plants, managing valve actuations, pressure sensors, and temperature controls with high precision to maintain safety and efficiency. Additionally, its application in general automation includes assembly lines and process control where its rapid data processing and robust construction minimize downtime and maintenance costs.

When compared to other Applied Materials models, the 0040-86650 REV. 003 offers unique advantages. For instance, while the Applied Materials 0040-76677 provides solid I/O capabilities, it lacks the advanced EMI shielding and extended protocol support found in the 0040-86650 REV. 003. Similarly, the Applied Materials 0190-09419 is optimized for simpler automation tasks but does not match the high-density input/output capacity or rugged design of the 0040-86650 REV. 003. The Applied Materials EFEM IO CONTROLLER is tailored for wafer handling systems, which makes the 0040-86650 REV. 003 a more suitable choice for power and petrochemical industries due to its durability and broader application scope.

Alongside the Applied Materials 0040-86650 REV. 003, other complementary products such as the Applied Materials 0090-00836 and Applied Materials 0190-35864 extend the automation capabilities by providing specialized interface modules and communication adapters. The Applied Materials 0010-37866W and 0020-34696 serve as reliable power supply units and signal conditioners, enhancing the overall system performance. For enhanced environmental protection, the Applied Materials 0040-07033 enclosure options ensure the 0040-86650 REV. 003 and its counterparts maintain peak functionality in harsh conditions. The Applied Materials 0100-09054 and 0190-01720 models integrate seamlessly for advanced sensor management and data acquisition tasks, elevating the efficiency of industrial automation setups.

The application of 0040-86650 REV. 003 in the power industry, petrochemical, and general automation sectors is significant due to its ability to reduce operational risks and improve process accuracy. Its compatibility with a wide array of industrial protocols and its rugged design make it a preferred choice for engineers aiming to future-proof their automation infrastructure. Additionally, the model’s modular design allows for easy upgrades and maintenance, ensuring minimal disruption during system expansions or repairs.

In summary, the Applied Materials 0040-86650 REV. 003 is a high-performance automation product designed to deliver reliable, high-speed control and monitoring in demanding industrial environments. Its superior input/output density, advanced durability features, and versatile communication support distinguish it from other models like the Applied Materials 0040-76677, 0190-09419, and EFEM IO CONTROLLER. Integrated within a comprehensive automation system alongside models such as the Applied Materials 0090-00836, 0010-37866W, 0020-34696, and 0100-09054, it ensures optimal control across a variety of applications. Whether deployed in power industry substations, petrochemical processing plants, or general automation frameworks, the 0040-86650 REV. 003 continues to set the benchmark for performance and reliability in Applied Materials automation products.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|