K-WANG

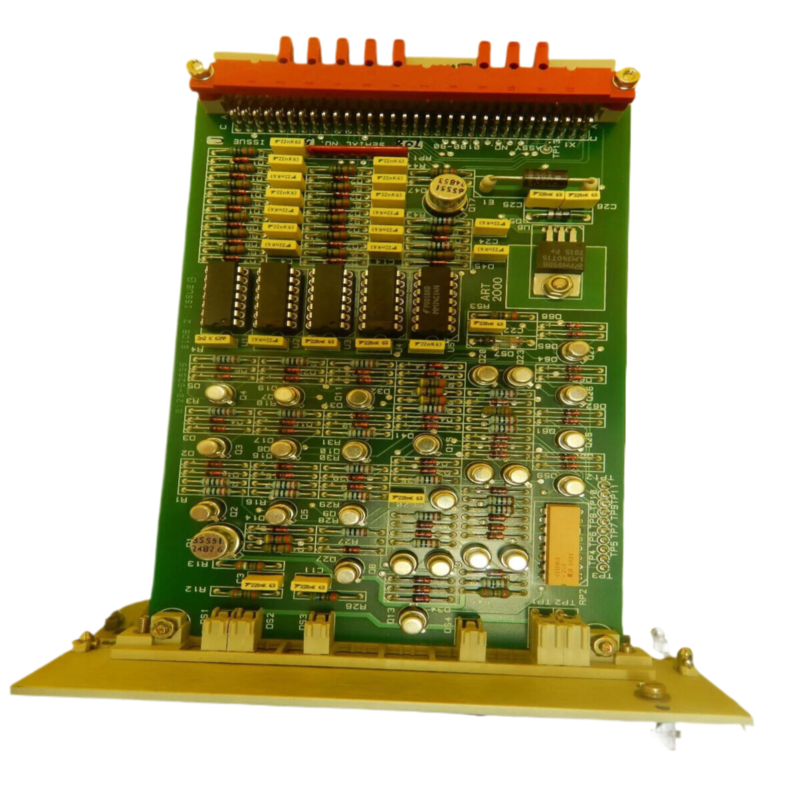

Applied Materials 0010-25482 - AMAT CHAMBER MODULE CONTROLLER

The Applied Materials 0010-25482 is a high-performance automation component engineered to meet the demanding requirements of the power industry, petrochemical sectors, and general automation applications. Renowned for its robust build and precise operational capabilities, this model delivers exceptional input/output capacity, enhanced durability, and reliable performance metrics tailored to optimize industrial automation processes.

At the heart of the Applied Materials 0010-25482 is its advanced I/O handling capability, designed to support high-throughput environments where rapid data exchange and control signal processing are crucial. This model facilitates seamless integration with complex automation systems, supporting a broad range of input signals and offering multiple output channels to ensure efficient coordination of machinery and process controls. Its superior signal fidelity and low latency response make it ideal for critical operations where timing and accuracy are paramount.

Durability is a cornerstone of the 0010-25482’s design. Built to withstand harsh industrial conditions, it features ruggedized components that resist temperature fluctuations, vibrations, and electrical noise typically encountered in power plants and petrochemical facilities. This resilience translates into extended service life and reduced maintenance downtime, ensuring continuous operation in environments where reliability cannot be compromised.

Performance metrics for the Applied Materials 0010-25482 include rapid processing speeds, high signal-to-noise ratios, and precise control capabilities. These specifications enable it to support complex automation sequences, maintain tight process tolerances, and adapt dynamically to changing operational demands. This model’s compatibility with standard industrial communication protocols further enhances its versatility, making it a preferred choice for system integrators and facility managers looking for dependable automation products.

In real-world scenarios, the application of 0010-25482 in the power industry often involves monitoring and controlling critical parameters such as voltage, current, and temperature within power generation and distribution systems. Its precision and durability ensure that power plants maintain optimal performance and safety standards. Similarly, in petrochemical environments, the 0010-25482 excels by managing automated valves, sensors, and safety interlocks, supporting complex chemical processing workflows with minimal risk of failure. For general automation, it provides scalable solutions suitable for factory automation, robotics, and process control, offering flexibility to adapt across diverse manufacturing setups.

When compared to other Applied Materials automation products, the 0010-25482 stands out due to its balanced combination of input/output capacity and ruggedness. For example, the Applied Materials 0010-20705 and Applied Materials 0010-26439 also serve automation purposes but typically cater to less demanding environments with lower throughput requirements. The 0010-25482, by contrast, is optimized for high-load applications, outperforming models like Applied Materials 0090-04412 and Applied Materials 0200-03313 in terms of response time and durability under industrial stress. Additionally, models such as the Applied Materials 0010-42741 and Applied Materials 0200-10144 are specialized for niche automation tasks, whereas the 0010-25482 offers a more versatile profile suitable for a broader range of applications.

Alongside the Applied Materials 0010-25482, we also offer complementary models such as the Applied Materials 0010-18024 and Applied Materials 0150-18894 Rev 2, which provide enhanced interface options for expanded system integration. The Applied Materials 0200-36649 and Applied Materials 0020-36036 support auxiliary control functions that pair well with the 0010-25482’s core capabilities. For applications requiring advanced sensor interfacing and precision control, the Applied Materials 0010-30256 and Applied Materials 0190-26495 are excellent adjuncts, delivering additional sensory input and output channels. Furthermore, the Applied Materials 0010-49041 and Applied Materials 0010-24794 models can be integrated to extend automation system scalability and redundancy, ensuring uninterrupted operation in mission-critical environments.

In summary, the Applied Materials 0010-25482 is a top-tier automation product designed for the rigorous demands of the power industry, petrochemical plants, and general automation fields. Its exceptional input/output capacity, robust durability, and superior performance metrics distinguish it from other Applied Materials models, making it an indispensable component for modern industrial automation. Whether integrated within a standalone system or as part of a broader network of Applied Materials products, the 0010-25482 consistently delivers precision, reliability, and efficiency, meeting the highest standards expected from Applied Materials automation products.

For industries seeking to enhance operational control, improve system reliability, and optimize process automation, the application of 0010-25482 in power industry, petrochemical, and general automation settings offers a proven solution that drives productivity and ensures long-term value.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|