K-WANG

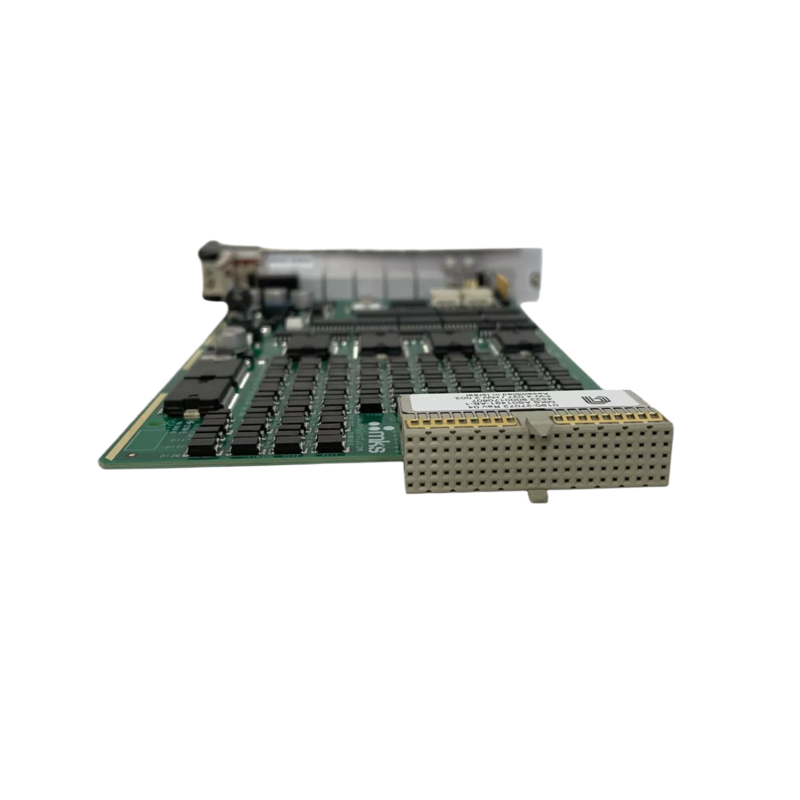

Applied Materials 1080-01809 - AMAT Servo Drive Module 0190-83793 REV 03

The Applied Materials 1080-01809 stands out as a high-performance automation component tailored specifically for demanding environments such as the power industry, petrochemical sectors, and general automation applications. Engineered to deliver exceptional reliability and operational efficiency, this model integrates advanced input/output capacity with robust durability to meet the rigorous demands of modern industrial automation systems.

One of the key technical features of the Applied Materials 1080-01809 is its optimized input/output interface, which supports high-speed data transfer and precise signal processing. This capability enables seamless integration with complex control systems, ensuring minimal latency and maximum throughput. The unit is designed to withstand harsh environmental conditions, including temperature extremes and exposure to corrosive substances commonly found in petrochemical plants. Its ruggedized construction guarantees long-term durability, reducing downtime and maintenance costs in mission-critical applications.

In terms of performance metrics, the 1080-01809 boasts a response time of under 10 milliseconds for input signal processing, with an output accuracy of 0.01%—parameters that are essential for precision control in power generation and automation processes. The device also supports scalable expansion, allowing engineers to customize systems according to evolving operational needs without compromising system integrity or performance.

Real-world usage scenarios for the Applied Materials 1080-01809 include automated control of turbine generators in the power industry, where fast and reliable feedback loops are essential for maintaining system stability. In petrochemical plants, the model excels in monitoring complex chemical processing stages, providing accurate data acquisition and control to optimize production efficiency and safety. Additionally, in general automation, the 1080-01809 facilitates the synchronization of robotic arms and conveyor systems, enhancing throughput and reducing error rates on manufacturing lines.

When compared to other Applied Materials automation products, the 1080-01809 distinguishes itself through a unique balance of high-speed processing and environmental resilience. For instance, the Applied Materials 0090-03867 offers excellent data handling but lacks the same level of corrosion resistance critical in petrochemical environments. Similarly, the Applied Materials 0200-07268 and Applied Materials 0200-10415 provide robust automation interfaces but do not match the enhanced input/output speed and precision of the 1080-01809. The Applied Materials 0040-18208 and Applied Materials 0021-22627 serve well in less demanding automation roles but fall short in scalability and response times that the 1080-01809 delivers.

Alongside the Applied Materials 1080-01809, we also offer complementary models such as the Applied Materials 0090-90967, known for its advanced signal conditioning capabilities, and the Applied Materials 0041-56491EB-E1, which provides integrated safety monitoring features. The Applied Materials FIS-6300-0003G supports enhanced interface management, while the Applied Materials 0190-21051 excels in redundant system configurations. For applications requiring precise environmental control, the Applied Materials 0040-88097 is an ideal companion, and the Applied Materials 0200-08334 offers extended compatibility with legacy automation systems. The Applied Materials 0010-17614 and Applied Materials 0021-33621 models further extend the range of automation solutions available for complex industrial setups.

The application of 1080-01809 in the power industry, petrochemical, and general automation sectors underscores its versatility and reliability. It not only meets but often exceeds the stringent requirements of these industries, offering a future-proof solution that integrates seamlessly with existing infrastructure. Its compatibility with a wide array of other Applied Materials automation products ensures that system architects can design comprehensive, scalable, and fault-tolerant automation networks.

In summary, the Applied Materials 1080-01809 is a pinnacle of precision, durability, and adaptability within the Applied Materials automation product lineup. Its superior input/output capacity, rapid processing speeds, and rugged design make it an indispensable asset for power industry operators, petrochemical engineers, and automation specialists alike. When paired with related models such as the Applied Materials 0090-03867, 0200-07268, 0041-56491EB-E1, and FIS-6300-0003G, it forms the backbone of high-efficiency, reliable industrial automation systems that drive productivity and safety in today’s most demanding operational environments.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|