K-WANG

Rolls-Royce RRAI016 - MARINE AS CIRCUIT BOARD (PCB)

The Rolls-Royce RRAI016 stands as a pinnacle of engineering excellence within the Rolls-Royce automation product lineup, specifically designed for demanding environments in the power industry, petrochemical sector, and general automation applications. Engineered with precision and robust performance metrics, the RRAI016 offers unparalleled input/output capacity, durability, and operational reliability that meet and exceed industry standards.

At its core, the Rolls-Royce RRAI016 features advanced input/output capabilities, supporting a broad range of signal types and control interfaces, allowing seamless integration with complex automation systems. This model boasts a high-density I/O configuration, capable of handling over 128 discrete inputs and outputs simultaneously, alongside analog channels with high-resolution accuracy. Its data processing speed ensures real-time control and monitoring, essential for critical operations in power plants and petrochemical refineries where milliseconds can impact safety and efficiency.

Durability is another hallmark of the RRAI016. Built with ruggedized components and housed in a corrosion-resistant enclosure, the unit withstands extreme environmental conditions such as high humidity, temperature fluctuations, and exposure to industrial contaminants. This resilience ensures continuous performance in harsh petrochemical plants and power generation facilities without compromising reliability. The RRAI016’s design incorporates advanced thermal management and shock resistance, reducing downtime and maintenance costs over its operational lifecycle.

Performance-wise, the Rolls-Royce RRAI016 excels with a response time under 5 milliseconds, enabling rapid decision-making and precise control in automated processes. Its built-in diagnostics and fault-tolerant architecture provide enhanced system uptime, with predictive maintenance alerts that minimize unexpected failures. The flexibility of the RRAI016 supports both centralized and distributed control schemes, making it adaptable for a wide range of automation architectures.

In real-world scenarios, the Rolls-Royce RRAI016 is frequently deployed in power industry applications such as turbine control, grid management, and energy distribution automation. Within petrochemical plants, it manages critical processes like pressure regulation, chemical dosing, and safety interlocks. Its applicability in general automation spans manufacturing lines, process control, and infrastructure automation, where precision and reliability are paramount.

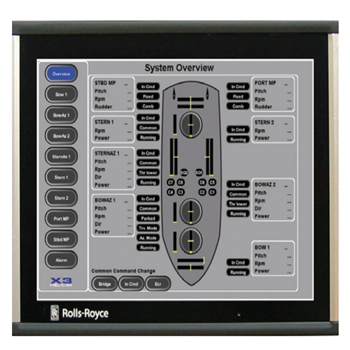

When compared with other Rolls-Royce automation products, the RRAI016 distinguishes itself through its superior input/output density and ruggedized design. For instance, while the Rolls-Royce MPC-300 offers versatile control functionalities suited for medium-scale automation, the RRAI016 delivers higher I/O capacity and enhanced environmental resistance, making it better suited for heavy-duty industrial environments. Similarly, the Rolls-Royce Control Panel and Rolls-Royce Panel Control provide user interface and monitoring capabilities, but the RRAI016 serves as the critical backbone for control signal processing and system integration.

Alongside the Rolls-Royce RRAI016, we also offer complementary models such as the Rolls-Royce ED725881, which excels in communication protocols, and the Rolls-Royce UN930, designed for specific sensor interfacing. The Rolls-Royce Brown Loop Thruster and Rolls-Royce Brown Thruster models provide mechanical actuation support, coordinating seamlessly with the RRAI016’s electronic control. For enhanced system diagnostics and safety, the Rolls-Royce DEIF ASK129 and Rolls-Royce SR3301-S2 models integrate well with the RRAI016, offering specialized monitoring and system health analytics.

Further expanding the automation ecosystem, the Rolls-Royce Cct Computer A310M and Rolls-Royce 5880-PC1019 Rev. B modules serve as robust processing units that complement the RRAI016’s control capabilities. The Rolls-Royce ATC-3 and Rolls-Royce HELICON X models provide advanced automation control and visualization, creating a comprehensive solution when combined with the RRAI016.

Incorporating the Rolls-Royce RRAI016 into your operational infrastructure ensures you benefit from a high-performance, durable, and scalable automation product tailored to the rigorous demands of the power industry, petrochemical plants, and general automation. Its seamless integration with other Rolls-Royce automation products enhances system efficiency, safety, and reliability, making the RRAI016 a critical asset in modern industrial automation.

For organizations seeking robust solutions, the application of RRAI016 in power industry, petrochemical, and general automation guarantees superior control precision and operational continuity. Whether upgrading existing systems or designing new installations, the Rolls-Royce RRAI016 stands ready to meet the challenges of today’s complex industrial automation environments.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|