K-WANG

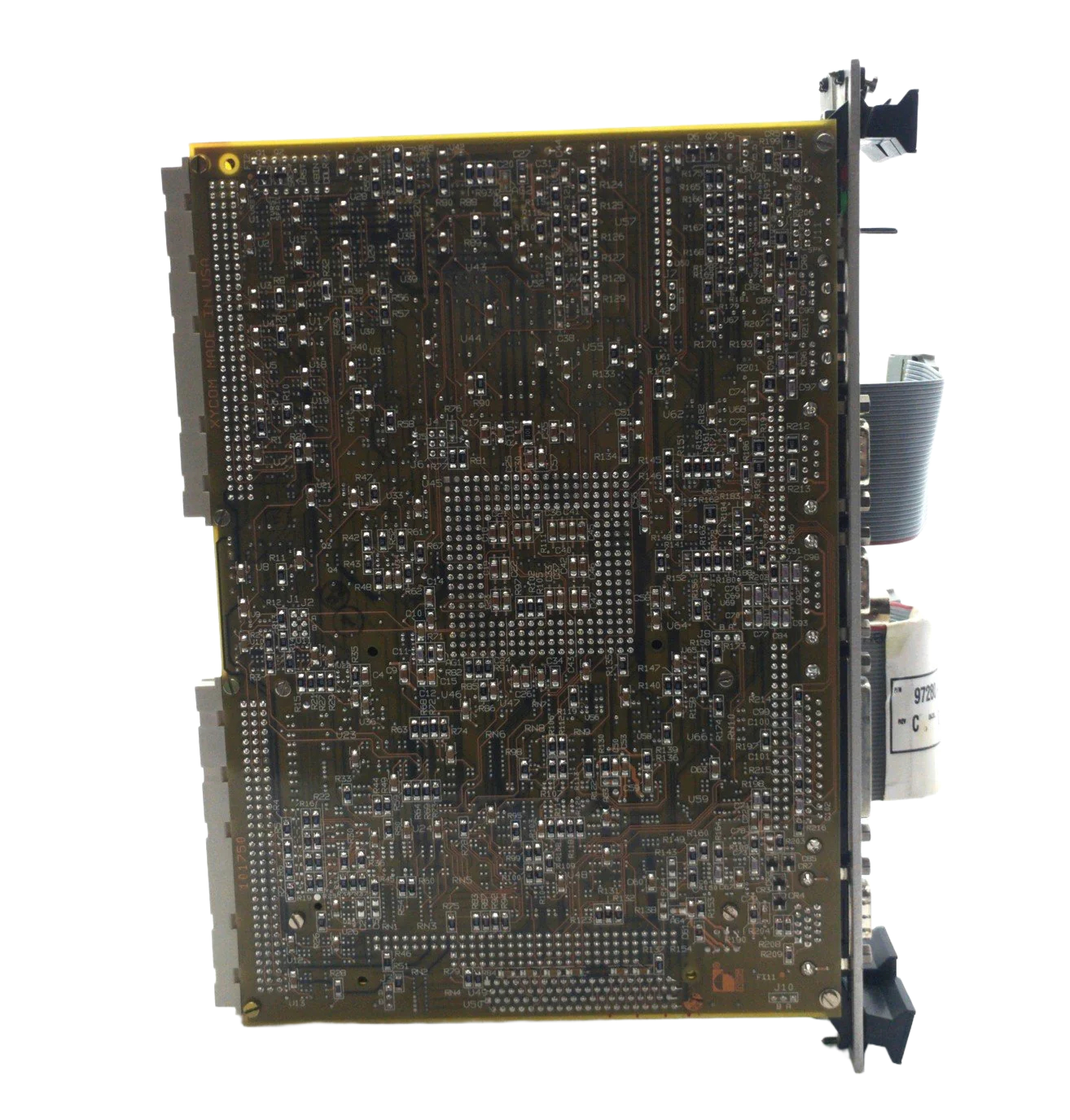

Xycom 2000T-97957-101 - Repair Evaluation

The Xycom 2000T-97957-101 stands as a robust and highly versatile automation solution, engineered specifically to meet the demanding requirements of the power industry, petrochemical sector, and general automation applications. Built to deliver precise control and reliable performance in harsh industrial environments, this model incorporates advanced input/output (I/O) capacity and superior durability, making it an essential component for complex automated control systems.

One of the key technical features of the Xycom 2000T-97957-101 is its extensive I/O capability. Designed to handle a broad range of analog and digital signals, it supports up to 64 input channels and 64 output channels, facilitating expansive control over multiple process variables simultaneously. This high-density I/O capacity ensures seamless integration with various sensors, actuators, and control devices commonly found in power plants and petrochemical facilities. Furthermore, the 2000T-97957-101 offers exceptional signal processing speeds with a response time of under 5 milliseconds, enabling real-time data acquisition and control necessary for critical process automation.

Durability is another hallmark of the 2000T-97957-101. Constructed with industrial-grade materials and conforming to rigorous MIL-STD-810 standards, it is capable of withstanding extreme temperatures, vibration, and humidity. This ruggedness ensures uninterrupted operation even in challenging environments such as offshore petrochemical platforms or high-voltage power substations. Moreover, its modular design allows for easy maintenance and scalability, reducing downtime and facilitating system upgrades as operational demands evolve.

Performance metrics for the Xycom 2000T-97957-101 include a mean time between failures (MTBF) exceeding 100,000 hours, highlighting its reliability in continuous operation scenarios. The product also supports a wide operating voltage range (24V to 48V DC), enhancing compatibility with diverse power supply configurations commonly used in industrial automation.

In real-world applications, the Xycom 2000T-97957-101 excels in managing complex control loops and safety interlocks within power generation plants, where precise timing and fail-safe operation are paramount. In the petrochemical industry, it effectively coordinates process control systems that require accurate monitoring of pressure, temperature, and flow rates to ensure safe and efficient chemical reactions. Additionally, its adaptability to general automation tasks makes it suitable for assembly line automation, packaging machinery control, and facility management systems, providing flexibility across various industries.

When comparing the 2000T-97957-101 to other models within the Xycom portfolio, its unique combination of high I/O density, rapid response time, and extreme durability sets it apart. For instance, while the Xycom 2000T offers solid base functionality for general automation, the 2000T-97957-101 integrates enhanced signal processing and environmental resistance, making it better suited for harsh industrial settings. Similarly, unlike the Xycom 3512-KPT or the Xycom 3515-KPM-T, which are optimized for specific control protocols and moderate environmental conditions, the 2000T-97957-101 is engineered for multi-protocol compatibility and extreme environments, offering broader application flexibility.

Alongside the Xycom 2000T-97957-101, complementary models such as the Xycom DS200TBCAG1AAB and Xycom DS200DMCBG1AED provide specialized digital motion control modules that integrate seamlessly for enhanced automation system capabilities. The Xycom PM8450 and Xycom PM101683E serve as powerful peripheral modules, expanding system input/output options and enabling finer control granularity. The Xycom 9487-249001601 and Xycom 9485 modules support robust communication interfaces, ensuring reliable data exchange across distributed control systems. Additionally, the Xycom 9615T and Xycom 50151 offer compact I/O solutions for localized control tasks, complementing the broader scope of the 2000T-97957-101.

In terms of application, the Xycom 2000T-97957-101 is particularly effective in the power industry, where it manages turbine control processes, load distribution, and protective relay coordination. Its rugged design and fast response time make it indispensable in petrochemical plants for monitoring critical safety parameters and automating complex chemical processing sequences. The general automation sector benefits from the 2000T-97957-101’s adaptability to varied mechanical and electrical automation needs, from robotic assembly lines to HVAC control systems.

Overall, the Xycom 2000T-97957-101 is a cornerstone of Xycom automation products, delivering unmatched resilience, scalability, and performance. Its integration with related modules like the Xycom 112471-099 and Xycom 3510KP further enhances system versatility, making it a preferred choice for engineers seeking reliable automation solutions in highly demanding industries. Whether used in power generation, petrochemical refining, or broad

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|