K-WANG

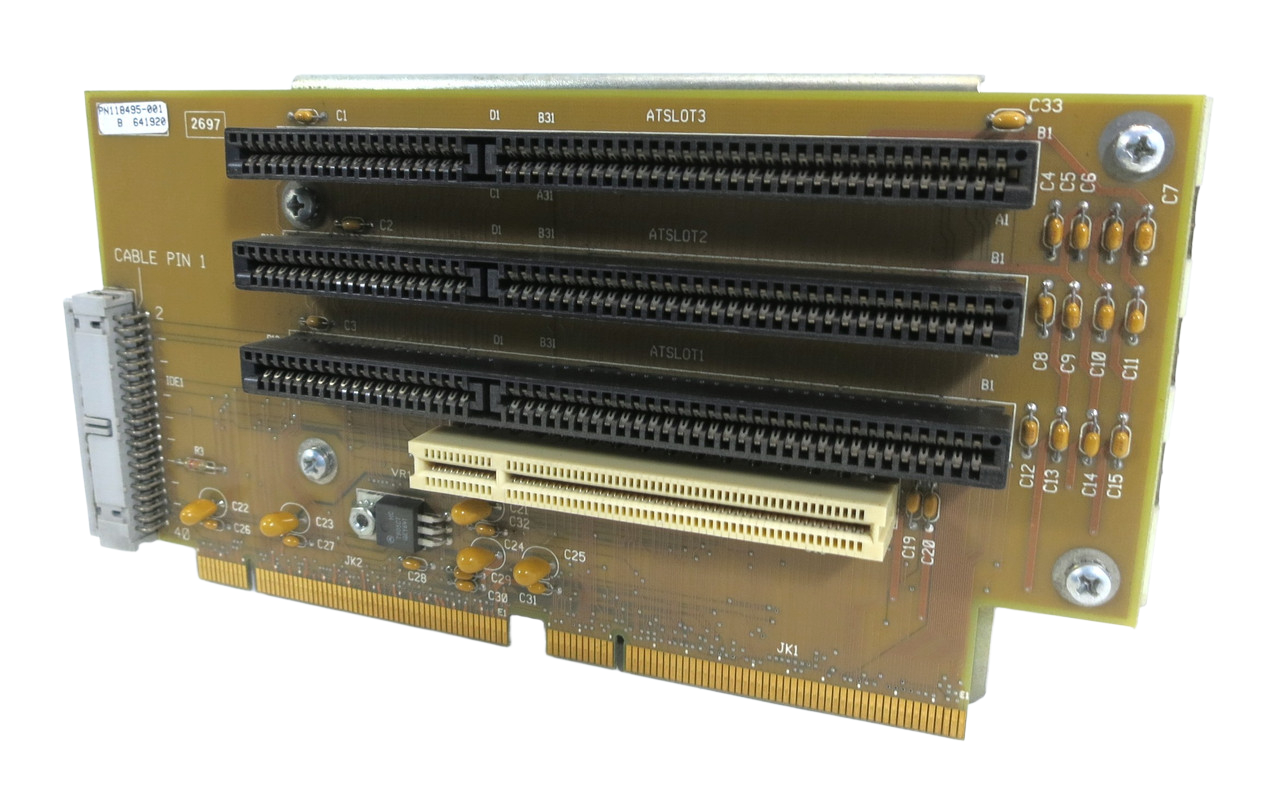

GE Fanuc DS200TCQBG1AGB - MARK V (R-S-T) EXTENDED ANALOG I/O BOARD

The GE Fanuc DS200TCQBG1AGB is a high-performance programmable logic controller (PLC) designed specifically to meet the rigorous demands of the power industry, petrochemical sectors, and general automation applications. Engineered for superior reliability and precision, the DS200TCQBG1AGB offers an advanced input/output (I/O) capacity that ensures seamless integration and real-time control in complex industrial environments. With its robust construction, this model guarantees durability even under extreme operating conditions, making it a preferred choice for mission-critical automation tasks.

At its core, the GE Fanuc DS200TCQBG1AGB features a versatile I/O configuration supporting a wide range of digital and analog inputs and outputs. Its architecture enables rapid processing speeds and efficient data handling, crucial for applications requiring high-speed response and accuracy. This PLC supports extensive communication protocols, allowing it to interface effortlessly with other automation components and supervisory systems. The DS200TCQBG1AGB’s rugged design includes enhanced resistance to electrical noise, temperature fluctuations, and mechanical vibrations, thereby ensuring continuous operation in harsh industrial settings.

In real-world scenarios, the application of DS200TCQBG1AGB in power industry environments is particularly noteworthy. It excels in controlling turbine operations, managing load distributions, and overseeing safety interlocks, enhancing overall plant efficiency and reliability. In petrochemical plants, the DS200TCQBG1AGB supports precise monitoring and control of complex chemical processes, ensuring safety compliance and minimizing downtime. Its adaptability also extends to general automation tasks such as assembly line control, packaging systems, and material handling, where precision timing and fault tolerance are critical.

When compared to other GE Fanuc automation products, the DS200TCQBG1AGB stands out for its balanced combination of performance, scalability, and robustness. For instance, while the GE Fanuc DS200TCCBG1AND offers similar control capabilities, the DS200TCQBG1AGB provides enhanced I/O flexibility and improved processing speeds, making it ideal for more demanding applications. Additionally, models like the GE Fanuc DS200TCEAG1ACB deliver solid performance but lack the advanced noise immunity features found in the DS200TCQBG1AGB, which are essential in electrically noisy environments common in power generation and petrochemical facilities.

Alongside the GE Fanuc DS200TCQBG1AGB, complementary automation components such as the GE Fanuc DS200SIOBH1AAA remote I/O modules and the GE Fanuc XVME-505 embedded controllers can be integrated to expand system capabilities and facilitate complex control architectures. For enhanced communication and data acquisition, the GE Fanuc 81626FA and GE Fanuc 144365-001 interfaces provide reliable connectivity solutions. The GE Fanuc 71110b1-001 and GE Fanuc 3512-KPM modules further augment system versatility by supporting additional analog and digital signal processing needs.

Moreover, the GE Fanuc DS200TCQBG1AGB can be effectively paired with the GE Fanuc 18765 and GE Fanuc 9487 for advanced monitoring and diagnostic functions, ensuring preventive maintenance and reducing unplanned outages. For applications requiring specialized motor control and power management, the GE Fanuc 3535 KPM and GE Fanuc 4715KPM-2000-1 are excellent complements, offering precision and energy efficiency.

The GE Fanuc DS200TCQBG1AGB not only reflects the legacy of GE Fanuc automation products in delivering reliable industrial control solutions but also represents a forward-thinking approach to automation. It combines the best features found in legacy models like the GE Fanuc 2000-KB2 and the GE Fanuc 99222-001 with modern enhancements tailored for today’s industrial challenges. This model’s versatility and robustness make it invaluable for engineers and system integrators seeking dependable performance across a spectrum of applications.

In summary, the GE Fanuc DS200TCQBG1AGB stands as a cornerstone in the portfolio of GE Fanuc automation products, offering unmatched durability, flexible I/O capacity, and superior performance metrics. Its application in the power industry, petrochemical plants, and general automation sectors ensures seamless control, improved safety, and operational efficiency. When combined with other trusted GE Fanuc models such as the DS200SIOBH1AAA, XVME-505, 81626FA, and 3535 KPM, the DS200TCQBG1AGB forms the backbone of sophisticated automation solutions designed to meet and exceed industry standards.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|