K-WANG

NI PXI-2798 - PXI RF Switch Module

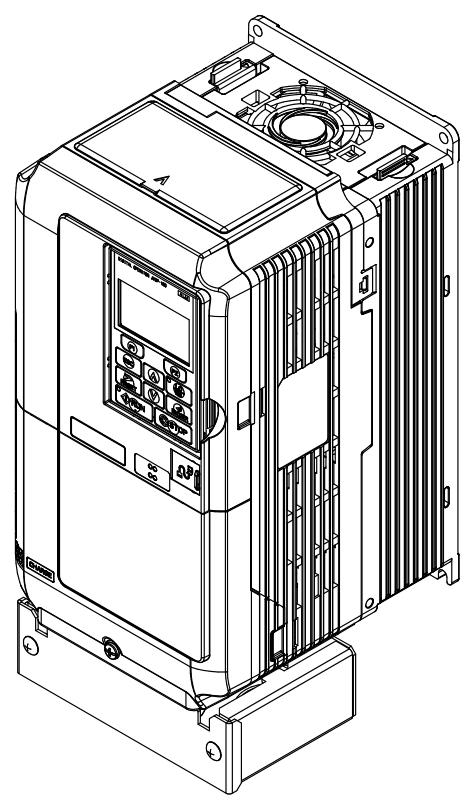

The NI PXI-2798 is a high-performance PXI chassis designed to meet the rigorous demands of power industry, petrochemical, and general automation applications. Engineered for reliability and scalability, the PXI-2798 offers superior input/output capacity and robust durability, making it an essential component in advanced test and measurement systems. Its architecture supports high-density module slots, providing a flexible platform for integrating a wide range of NI automation products to optimize system performance.

One of the standout technical features of the NI PXI-2798 is its comprehensive I/O capacity. The chassis supports up to 18 PXI and PXIe hybrid slots, enabling users to deploy a diverse array of measurement and control modules from NI’s extensive product portfolio. The PXI-2798 also incorporates a high-bandwidth backplane, which delivers data transfer rates up to 4 GB/s. This capability is critical for applications requiring real-time data acquisition and processing, such as power grid monitoring and petrochemical process control. In addition, the chassis is designed for exceptional durability with rugged construction and efficient cooling mechanisms to ensure reliable operation in harsh industrial environments.

Performance metrics of the NI PXI-2798 emphasize its suitability for demanding automated testing scenarios. The chassis supports a system timing and synchronization framework that enables precise coordination across multiple modules, facilitating complex testing sequences and reducing measurement uncertainty. Its modular design also allows for easy maintenance and upgrades, extending the lifecycle and adaptability of the system.

In real-world usage, the NI PXI-2798 excels in environments where high channel counts and rapid data throughput are essential. In the power industry, it serves as the backbone for grid simulation and protection relay testing, where timely and accurate data acquisition is critical for system stability. In petrochemical applications, the PXI-2798 supports continuous monitoring of process variables, enabling operators to maintain safety and optimize production efficiency. Moreover, its versatility makes it ideal for general automation tasks, such as factory floor testing and embedded device validation, where integration with other NI instruments enhances overall system capabilities.

When compared to other models in the NI lineup, the PXI-2798 distinguishes itself through its combination of slot density, hybrid compatibility, and data throughput. For instance, while the NI PXIe-6535 digital I/O module provides high-speed digital communication, the PXI-2798 chassis acts as the foundational platform that accommodates such modules alongside others like the NI PXI-6230 multifunction DAQ or the NI PXIe-6366 high-speed digitizer. Unlike smaller chassis such as the NI PXI-2815 or the NI PXI-2865, which offer fewer slots and limited scalability, the PXI-2798 supports larger, more complex test systems without compromising performance.

Alongside the NI PXI-2798, users often integrate complementary models such as the NI PXI-2590 for dynamic signal analysis, the NI PXI-6259 for multifunction data acquisition, and the NI PXIe-4498 for high-fidelity audio and vibration measurements. The NI PXIe-6738 digital I/O module and the NI PXI-6624 counter/timer further enhance system flexibility, while the NI PXI-6123 provides high-speed analog input capabilities. For embedded control and real-time processing, the NI cRIO-9043 and NI cRIO-9048 offer FPGA-based solutions that can be synchronized with PXI systems, expanding the range of automation possibilities.

The application of PXI-2798 in the power industry, petrochemical, and general automation sectors is supported by its ability to integrate seamlessly with other NI automation products, creating a cohesive, high-performance test environment. This integration ensures that engineers and technicians can build scalable systems tailored to their specific testing and measurement needs, whether it’s simulating power system faults, monitoring chemical process variables, or automating quality control tests on a production line.

In summary, the NI PXI-2798 is a pivotal element within NI’s automation portfolio, delivering unmatched input/output capacity, durability, and performance. Its hybrid slot configuration, high data throughput, and robust design make it ideal for complex, high-channel-count applications across multiple industries. When paired with complementary modules such as the NI PXIe-6535, NI PXI-6230, NI PXIe-6366, NI PXI-2590, NI PXI-6259, NI PXIe-4498, NI PXIe-6738, NI PXI-6624, NI PXI-6123, and NI cRIO-9043, the PXI-2798 enables engineers to create modular, scalable systems that meet the evolving challenges of automation today. Whether deploying in the power industry, petrochemical plants, or general automation settings, the NI PXI-2798 offers a reliable, high-performance foundation for advanced testing and measurement solutions.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|