K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Brand

Description

Introducing the ABB IRB 6640-3HAC028470-001: Redefining Automation Excellence

ABB IRB 6640-3HAC028470-001 - Advanced Balancing Device

ABB IRB 6640-3HAC028470-001 - Advanced Balancing Device

Introducing the ABB IRB 6640-3HAC028470-001: Redefining Automation Excellence

The ABB IRB 6640-3HAC028470-001 is a state-of-the-art industrial robot designed to elevate productivity and precision in various manufacturing environments. As part of ABB’s comprehensive range of automation products, this model stands out for its robust engineering, versatility, and efficiency. With a remarkable balance of speed and payload capacity, the IRB 6640 is engineered to meet the diverse needs of modern industries, from automotive to electronics, and beyond.

Key Technical Features

The ABB IRB 6640-3HAC028470-001 boasts an impressive array of technical specifications that make it a preferred choice for businesses seeking to enhance their automation processes:

1. **Payload Capacity:** With a maximum payload of up to 150 kg, the IRB 6640 can handle heavy components and assemblies, making it ideal for demanding applications.

2. **Reach:** This robot features a reach of up to 2.6 meters, allowing it to access larger workspaces and perform intricate tasks without the need for repositioning.

3. **Speed and Precision:** The IRB 6640 is designed for high-speed operation, with a maximum speed of 2.5 m/s. Its precision is further enhanced by advanced control algorithms, ensuring that operations are executed with minimal deviation.

4. **Compact Design:** The robot's compact design means it can be integrated into existing production lines without requiring extensive modifications, saving both time and resources.

5. **Flexibility:** Equipped with a flexible wrist, the IRB 6640 can perform a wide range of movements, making it suitable for various tasks, including welding, material handling, and assembly.

6. **User-Friendly Interface:** The intuitive programming interface allows operators to easily configure and manage the robot, reducing training time and improving overall productivity.

Usage Scenarios

The versatility of the ABB IRB 6640-3HAC028470-001 makes it suitable for a variety of applications across diverse industries:

1. **Automotive Manufacturing:** The IRB 6640 excels in welding, painting, and assembly tasks, contributing to increased efficiency in automotive production lines.

2. **Electronics Assembly:** With its precision and dexterity, this robot is perfect for assembling delicate electronic components, ensuring high-quality outputs.

3. **Material Handling:** The IRB 6640 can automate the loading and unloading of goods, significantly streamlining warehouse operations.

4. **Packaging:** In the packaging sector, this robot can handle products with speed and accuracy, improving throughput and reducing labor costs.

5. **Food and Beverage Industry:** The robot's ability to handle heavy loads and operate in various environments makes it suitable for tasks like palletizing and sorting in food processing plants.

Comparison with Other Models

When comparing the ABB IRB 6640-3HAC028470-001 with other models in ABB's extensive range of automation products, several key differences emerge:

- **ABB IRB 2600:** While the IRB 2600 is renowned for its compact design, the IRB 6640 offers greater payload capacity and reach, making it better suited for heavy-duty applications.

- **ABB IRB 2400:** Both robots are versatile; however, the IRB 6640’s enhanced speed and payload capabilities give it an edge in high-demand environments.

- **ABB IRB 140:** The IRB 140 is designed for smaller tasks with lower payloads. In contrast, the IRB 6640 is a powerhouse for larger, more complex operations.

- **ABB IRB 6700:** Although the IRB 6700 is designed for ultra-heavy payloads, the IRB 6640 provides a balance of payload capacity and flexibility, making it a more versatile option for varied applications.

Related Models

To provide a comprehensive understanding of ABB's offerings, consider these related models that complement the capabilities of the IRB 6640:

1. **ABB UNS1860B-P** – Designed for precision applications requiring high performance.

2. **ABB PCD231 | 3BHE025541R0101** – Ideal for automation control in process industries.

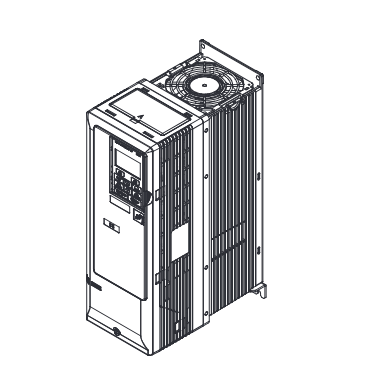

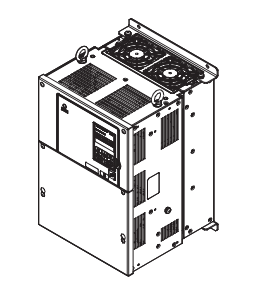

3. **ABB ACS880-01-246A-3** – A robust drive solution that enhances the performance of automation systems.

4. **ABB PM511V16 3BSE011181R1** – A powerful programmable controller that works seamlessly with ABB robots.

5. **ABB SC540** – A flexible controller that can optimize the operation of various robotic systems.

6. **ABB DSQC352B** – A digital servo controller that enhances motion control in robotic applications.

7. **ABB 3HAC027569-001** – A communication processor that integrates with the IRB series for enhanced connectivity.

8. **ABB NAIO-03F** – A compact robot designed for light assembly tasks, complementing the IRB 6640 in smaller applications.

9. **ABB 3HAC022436-001** – A sensor module that improves the precision and functionality of ABB robots.

10. **ABB IRB 140 Series** – A smaller form factor robot that excels in applications requiring agility and precision.

Conclusion

The ABB IRB 6640-3HAC028470-001 is a remarkable addition to ABB's lineup of automation products, delivering exceptional performance, flexibility, and reliability. Its advanced features and adaptability make it a vital tool for industries focusing on efficiency and precision. Whether you are in automotive manufacturing, electronics assembly, or materials handling, the IRB 6640 is engineered to meet your automation needs head-on, setting the stage for a more productive future. Explore the power of ABB automation products and unlock new levels of efficiency with the IRB 6640.

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Customer Reviews

Satisfaction :

5 Stars

No evaluation information