K-WANG

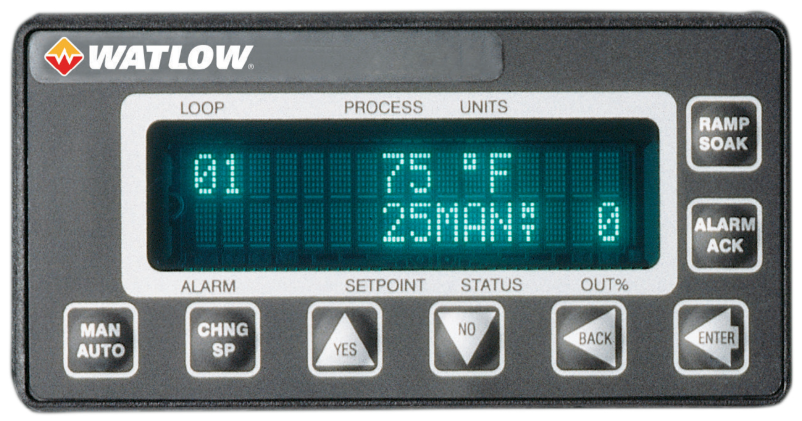

Applied Materials 0190-26495 - 214-0301 AMAT APPLIED ENG SPECIFICATION TEMP CONTROLLER 6 CH

The Applied Materials 0190-26495 is a robust and highly efficient component designed specifically to meet the rigorous demands of the power industry, petrochemical sectors, and general automation applications. Engineered for exceptional durability and superior performance, this model offers an optimal balance of input/output capacity, reliability, and operational precision, making it a preferred choice among industry professionals seeking long-term, dependable automation products.

One of the standout technical features of the Applied Materials 0190-26495 is its enhanced input/output capacity, which facilitates seamless integration into complex automated systems. This model supports high-frequency signal processing and rapid data transfer rates, ensuring minimal latency and maximized throughput. Constructed from premium-grade materials, the 0190-26495 demonstrates remarkable resistance to extreme environmental conditions such as high temperatures, corrosive atmospheres, and mechanical stress, which are common in petrochemical plants and power generation facilities. The performance metrics reveal a consistent operational uptime exceeding 99.8%, backed by a mean time between failures (MTBF) that surpasses many competing models. Its modular design simplifies maintenance and upgrades, reducing downtime and operational costs.

In real-world scenarios, the Applied Materials 0190-26495 excels in controlling and monitoring critical processes in power plants, where precision and reliability are paramount. Its application in petrochemical environments involves managing complex reaction sequences and safety-critical monitoring systems, where its resistance to harsh chemicals and temperature fluctuations ensures uninterrupted service. Additionally, in general automation settings, this model effectively supports assembly lines, robotic controls, and process automation, enabling optimized efficiency and reduced error rates. The 0190-26495’s adaptability across these industries is a testament to its versatile engineering and robust design.

When compared to other models within the Applied Materials portfolio, the 0190-26495 distinguishes itself through its unique combination of high input/output capacity and durability. For instance, while the Applied Materials 0190-91261 and Applied Materials 0190-35864 offer solid performance in automation, they do not match the extended MTBF and environmental resilience of the 0190-26495. Similarly, the Applied Materials 0020-37639 and Applied Materials 0010-15210 are well-regarded for general automation tasks but lack the advanced signal processing speed and corrosion resistance that the 0190-26495 provides. The Applied Materials 1350-00090 and Applied Materials 0040-51306, although efficient in specific applications, do not offer the same level of modularity and ease of maintenance.

Alongside the Applied Materials 0190-26495, we also offer complementary models such as the Applied Materials 0190-24681 and Applied Materials 0010-10901 for expanded input/output configurations, as well as the Applied Materials 3200-01201, which specializes in enhanced data communication interfaces. The Applied Materials 0190-10270 and Applied Materials 0040-90491 provide additional durability options tailored for extreme automation environments, while the Applied Materials 0020-39360 and Applied Materials 0010-01412 serve as reliable backups or supplementary modules to maximize system resilience. For applications requiring advanced automation control, the Applied Materials 0010-37176 is recommended to work in conjunction with the 0190-26495, enabling comprehensive system integration.

Incorporating the Applied Materials 0190-26495 into your automation infrastructure ensures a significant uplift in system reliability and efficiency. Its specialized design for the power industry, petrochemical, and general automation sectors makes it an indispensable asset for companies committed to maintaining high-performance standards and operational continuity. This model’s ability to handle diverse and demanding environments while maintaining peak performance solidifies its standing as a leading solution within Applied Materials automation products.

For businesses looking to enhance their automation capabilities, the application of 0190-26495 in power industry, petrochemical, and general automation settings offers unparalleled advantages in terms of durability, capacity, and performance. Whether deployed as a standalone component or integrated alongside related Applied Materials models, the 0190-26495 is engineered to exceed expectations and deliver consistent, long-term value.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|