K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Brand

Description

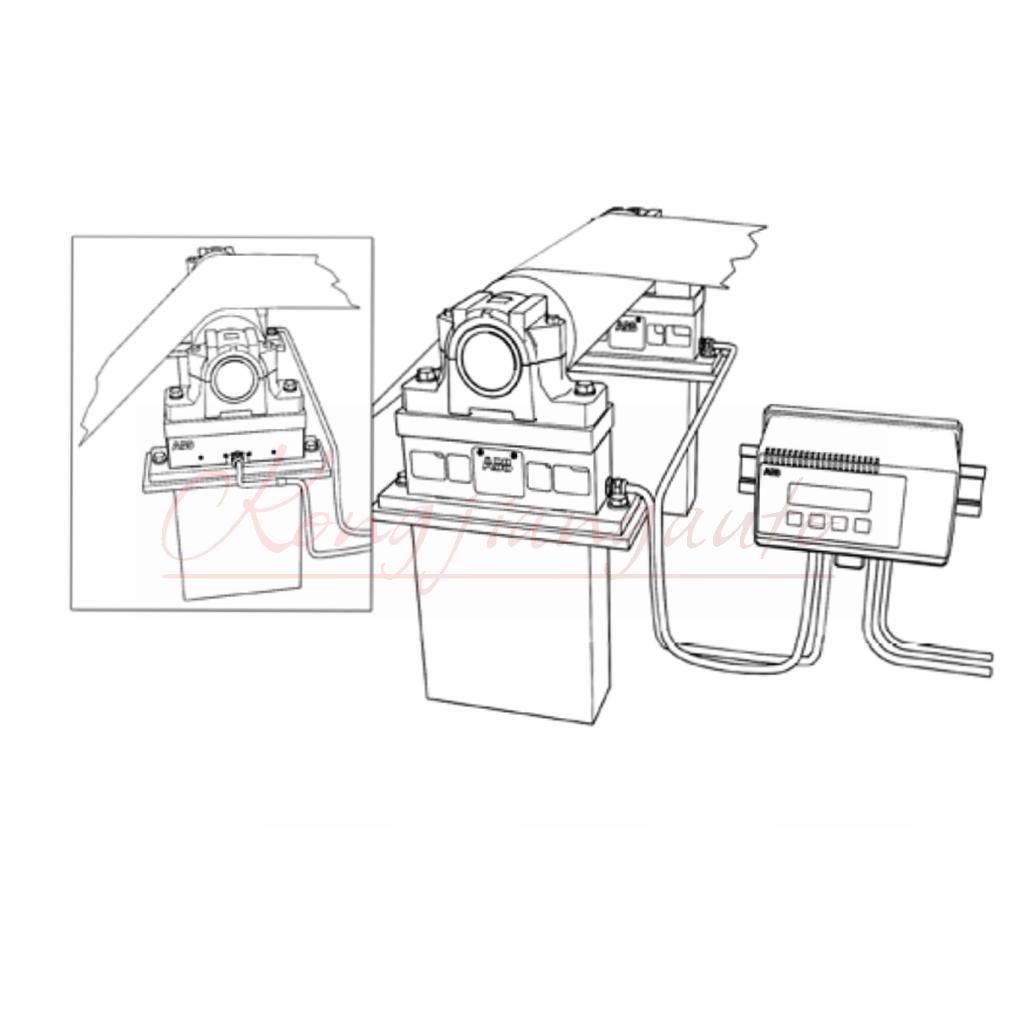

**Product Description: ABB NTDI02**

ABB NTDI02 - Digital Interface Termination Unit

ABB NTDI02 - Digital Interface Termination Unit

**Product Description: ABB NTDI02**

The ABB NTDI02 is a cutting-edge automation component designed to meet the rigorous demands of the power industry, petrochemical sectors, and general automation applications. Known for its robust performance and versatility, the NTDI02 stands out as an essential element in sophisticated control systems.

**Key Technical Features:**

The ABB NTDI02 boasts an impressive input/output capacity that enhances its functionality and adaptability. With a total of 32 digital inputs and 32 digital outputs, it ensures seamless integration and operation within complex automation frameworks. The unit is designed with durability in mind, featuring a rugged enclosure that withstands harsh environmental conditions—making it ideal for outdoor installations and industrial settings. Performance metrics indicate that the NTDI02 maintains high operational efficiency, with a response time of just 10 milliseconds, ensuring that real-time processing meets the demands of dynamic applications.

Furthermore, the NTDI02 is equipped with advanced diagnostic capabilities that enhance its reliability, allowing for rapid troubleshooting and maintenance, thereby minimizing downtime. The device adheres to international standards for safety and electromagnetic compatibility, ensuring that it operates safely in various environments.

**Real-World Usage Scenarios:**

In real-world applications, the ABB NTDI02 excels in environments where precision and reliability are paramount. For instance, in the power industry, it is employed to monitor and control energy distribution systems, helping utilities optimize grid performance. In petrochemical facilities, the NTDI02 facilitates automation processes such as monitoring pressure levels and flow rates, which are critical for maintaining operational safety and efficiency. Additionally, in general automation contexts, it is utilized in assembly lines to manage complex workflows, ensuring that production processes remain streamlined and effective.

**Comparison with Other Models:**

When compared to other models within the ABB brand, such as the ABB DSQC256A Sensor Module or the ABB PM633 3BSE008062R1, the NTDI02 offers unique advantages in terms of its high I/O capacity and faster response times. While the ABB DSQC256A specializes in sensor integration, the NTDI02’s broader input/output capabilities allow it to function effectively in a wider range of applications. Similarly, the ABB PM633 excels in process control but may not match the NTDI02's versatility and capacity, making the NTDI02 a more comprehensive choice for various automation needs.

**Complementary Models:**

The ABB NTDI02 works seamlessly with several related models to enhance overall system performance. For instance, integrating the ABB SMU-03 3HNA013638-001 with the NTDI02 can facilitate better motion control in robotic applications, while the ABB 3BHB020720R0002 power supply ensures reliable energy sources for the entire system. Additionally, the ABB 3HAC0277-2 communication module can be paired with the NTDI02 to enhance data transmission capabilities, making it an excellent choice for real-time monitoring and control scenarios.

Moreover, the NTDI02 complements the ABB 3BSE017193R1 NDCO03 Communication Card for efficient network integration, while the ABB AO561 Analog Output Module provides necessary analog signal processing. The ABB HEIR448194R1 UN0800A-P also integrates well with the NTDI02, facilitating robust automation in high-demand environments. Other models like the ABB 216NG63 HESG441635R1 Power Supply and ABB DSTK165 further enhance the operational capabilities of the NTDI02, providing necessary support for various automation tasks.

In summary, the ABB NTDI02 is an indispensable automation product that excels in the power industry, petrochemical applications, and general automation tasks. Its robust features, combined with the ability to integrate with other ABB automation products, make it the ideal choice for enhancing operational efficiency and reliability in industrial settings.

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Customer Reviews

Satisfaction :

5 Stars

No evaluation information