K-WANG

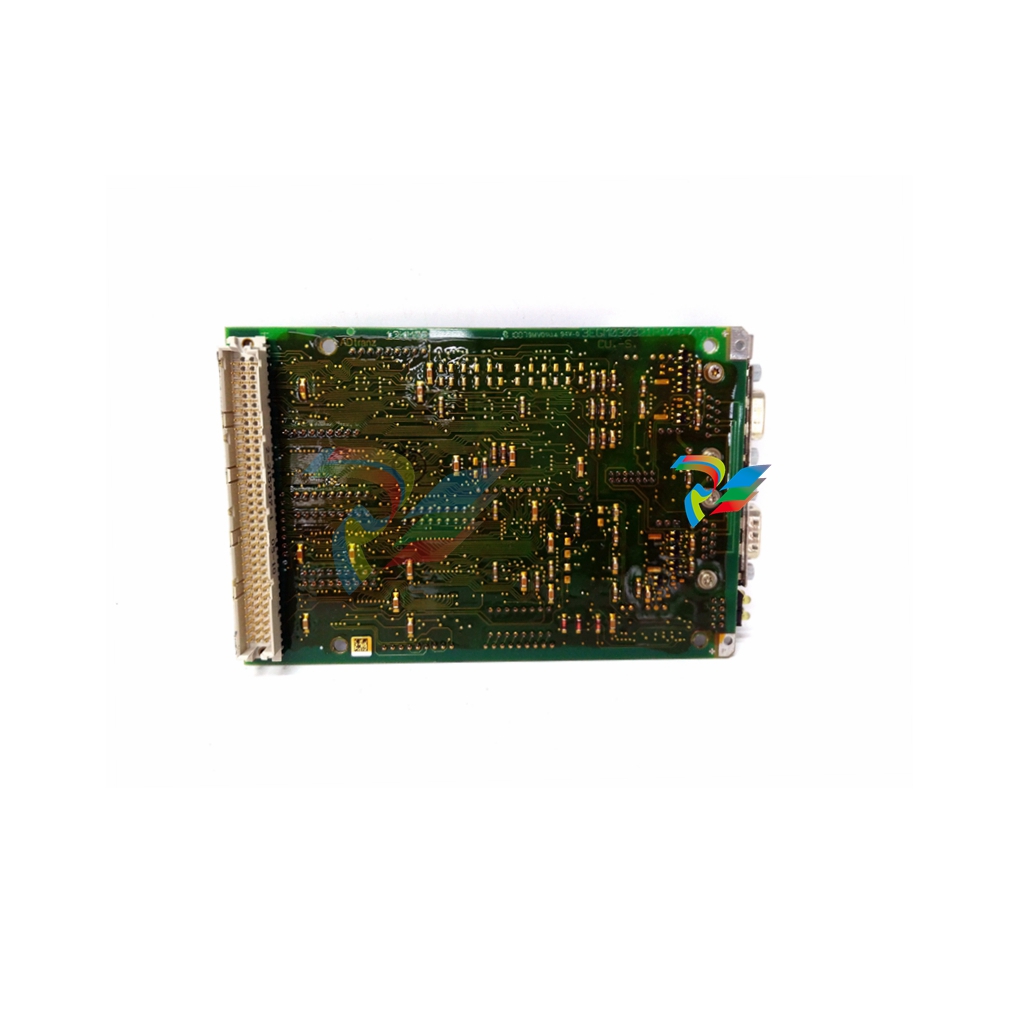

ABB TU811 - Terminal Unit

The ABB TU811 is a robust and versatile automation controller designed specifically to meet the demanding requirements of the power industry, petrochemical sector, and general automation applications. Built with precision engineering and leveraging ABB’s long-standing expertise in industrial automation, the TU811 offers a combination of high input/output capacity, exceptional durability, and reliable performance metrics that make it a preferred choice for critical infrastructure and complex process control environments.

At its core, the ABB TU811 features an extensive input/output (I/O) capacity that supports seamless integration with a wide range of field devices and sensors. This flexibility enables the TU811 to manage multiple data streams simultaneously, ensuring accurate real-time monitoring and control. The controller’s architecture is optimized for high-speed processing, delivering rapid response times essential for maintaining system stability and operational efficiency in sectors like power generation and petrochemical processing. Its rugged design ensures operational reliability even under harsh environmental conditions, including extreme temperatures, vibration, and electromagnetic interference, which are common challenges in industrial settings.

The TU811 excels in scenarios requiring precise automation control and data acquisition. In the power industry, it is widely deployed for tasks such as substation automation, load management, and fault detection, where its ability to handle high-volume data and execute complex control algorithms enhances grid reliability and safety. Petrochemical plants benefit from the TU811’s robustness and accuracy in managing continuous process variables, ensuring product quality and operational safety. Additionally, its adaptability makes it a valuable component in general automation systems where diverse device compatibility and real-time processing are essential.

When compared to other ABB automation products such as the TU810V1 or the PCD235B101, the TU811 stands out with its superior I/O scalability and enhanced processing speed, making it better suited for complex, data-intensive applications. While models like the ABB HIES208441R and ABB PFEA113-20 3BSE028144R0020 offer specialized functions for power protection and monitoring, the TU811 provides a more comprehensive control platform with broader applications across multiple industries. Its durability surpasses that of standard units such as the ABB EI803F and ABB DSAO120A 3BSE018293R1, which are often optimized for less demanding environments. Furthermore, the TU811’s integration capabilities are complemented by ABB’s extensive ecosystem, including devices like the ABB REM610 for remote monitoring and the ABB REG670 for advanced protection relays, allowing for a fully synchronized automation solution.

Alongside the ABB TU811, users can also consider the ABB SPCJ4D34-AA and ABB RED521 1MRK002003-BA for complementary functions such as system diagnostics and communication management. The ABB PPD517A3011 3BHE041576R3011 and ABB UBC717AE01 HIEE300927R0101 further enhance system reliability by providing specialized interfacing and backup control capabilities. In applications where human-machine interfaces are critical, the ABB REU615 panel integrates seamlessly with the TU811, offering intuitive control and visualization options. For environments requiring modular and scalable automation, the ABB 3BHE024415R0101 GVC714A101 and ABB DSRF182AK02 3BSE014078R1 models provide additional flexibility and redundancy options.

The application of TU811 in power industry, petrochemical, and general automation is characterized by its adaptability to complex network architectures and stringent safety standards. Its compatibility with ABB’s broader product range, including the ABB S3N 3P 150A circuit breakers and ABB FAZ-XHIN11 protection devices, ensures a cohesive and efficient automation ecosystem. This synergy enables operators to streamline maintenance, enhance fault tolerance, and optimize process control—all critical factors in high-stakes industrial operations.

In summary, the ABB TU811 is a high-performance automation controller that combines extensive I/O capabilities, rugged design, and fast processing speeds tailored for the rigors of power, petrochemical, and general automation industries. Its unique advantages over other ABB models, along with seamless integration into ABB’s comprehensive automation portfolio, make it an indispensable asset for operators seeking reliability, scalability, and operational excellence. Whether deployed in substations, chemical plants, or complex automated facilities, the ABB TU811 delivers precision control and enduring performance that drive industry-leading automation solutions.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|