K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Manufacturers

ABB

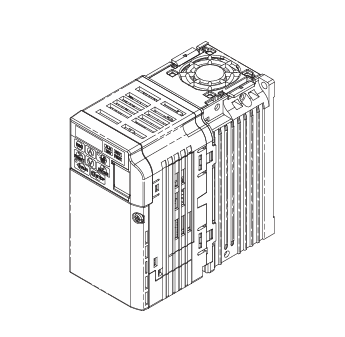

Model(s)

ABB Advant Controller 31, ABB Advant OCS

Estimated Shipping Size

Dimensions: 4.0" x 4.0" x 5.0"

(10.2 cm x 10.2 cm x 12.7 cm)

Weight: 0 lbs 12.0 oz (0.3kg )

ABB 1SBP2605002R1001 ICMK14F1 Remote Unit

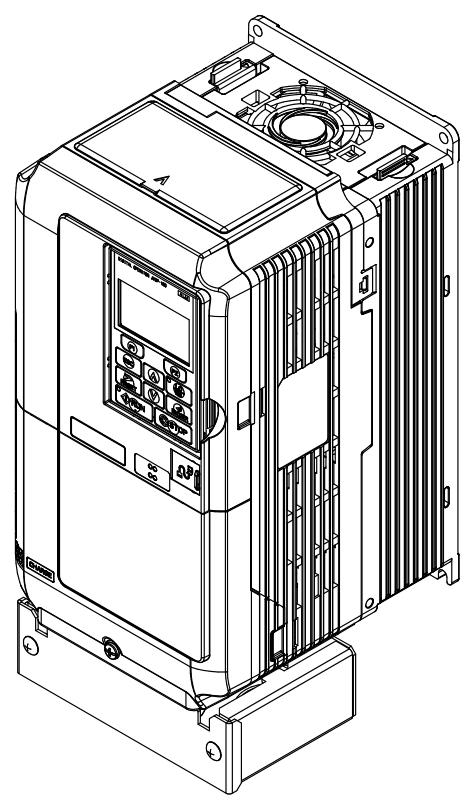

Overview: ABB 1SBP2605002R1001 ICMK14F1

The ‘1SBP2605002R1001’ in ABB 1SBP2605002R1001 ICMK14F1 Remote Unit is a specific model number used to accurately identify the remote unit; the ‘ICMK14F1’ indicates the specific type to which the remote unit belongs and identifies it within the ABB product range. ICMK14F1’ denotes the specific type of remote unit to which it belongs, and is its identity within the ABB product family.

Nature of the product: The product is a remote terminal unit, usually used in industrial automation control systems, to achieve the remote monitoring of field equipment and data acquisition and other functions.

Functional features

Data Acquisition: Equipped with eight 0-24V DC, 5mA input interfaces, it can be connected to a variety of sensors, such as temperature sensors, pressure sensors, etc., to collect a variety of analogue and digital data from the field in real time and convert them into digital signals that can be transmitted in the communication network.

Data processing: It can carry out preliminary processing of the collected data, such as filtering, calibration, calculation, etc., in order to improve the accuracy and reliability of the data, and provide powerful support for the subsequent data analysis and control decision-making.

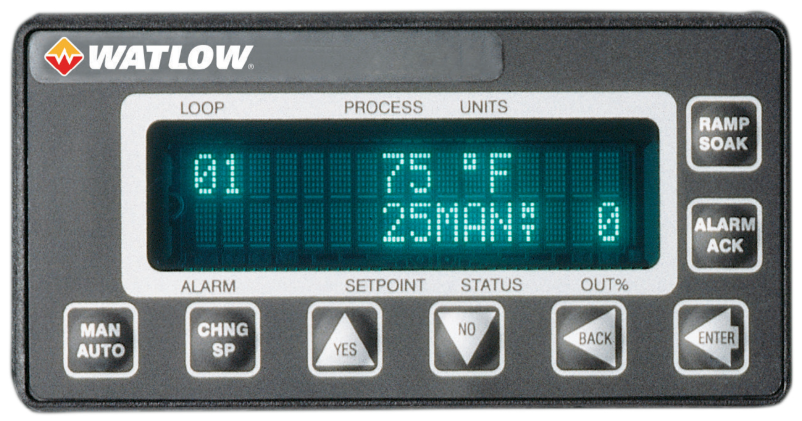

Remote control: It has 6 output interfaces, including 24V DC 2A/com C1, 24V DC 4A/com C2, 24V DC 8A, 120V AC 50-60Hz, 230V AC 50-60Hz 4A and other different specifications, which can be connected to the corresponding actuators according to the actual needs, such as motors, valves, etc., and receive commands from the central control system to achieve remote control of field equipment. Remote control of on-site equipment.

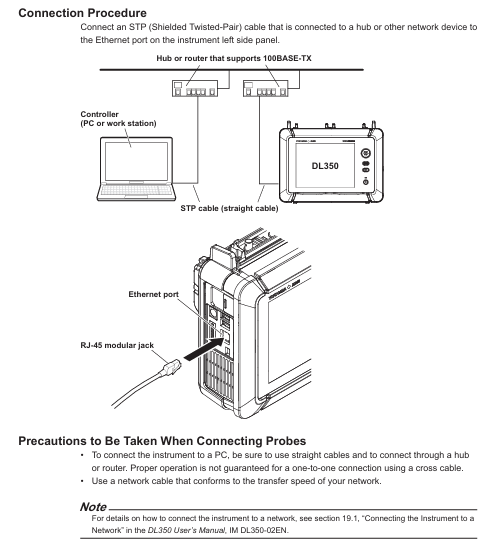

Communication function: Supporting various communication protocols and interfaces, it can communicate with the central control system or other devices through RS-485, Ethernet and other communication modes, upload the collected data to the central control system, and receive the control instructions from the central control system to ensure the stable operation of the remote monitoring system.

Technical Parameters

Power supply: 24V DC power supply, power consumption of 10W, this low-power design helps to reduce the operating costs of the equipment, but also easy to configure the power supply in the industrial field.

Input and output interfaces: Input interface is 8 0-24V DC, 5mA digital inputs, using AWG 14-24 Cu 8 Tr 60°C cable connection; Output interface is 6 digital outputs of different specifications, can meet the control needs of different load equipment.

Working environment: the working temperature range is generally wide, usually between - 20 ° C to + 70 ° C normal operation, can adapt to a variety of harsh industrial field environment; relative humidity range is generally 5% - 95% (non-condensing), can be in a humid environment stable operation.

Application Fields

Industrial automation: In the factory automation production line, it can be used to monitor and control the operation status of production equipment, such as collecting the temperature, pressure, flow and other parameters of the equipment, remote control of equipment start and stop, speed adjustment, etc., to improve production efficiency and product quality.

Power system: In substations, power plants and other places, it can be used to realise remote monitoring and data collection of power equipment, such as monitoring the oil temperature, voltage, current and other parameters of transformers, as well as remote control of switchgear to ensure the safe and stable operation of the power system.

Intelligent building: It can be applied to the HVAC system, lighting system and lift system of the intelligent building to achieve remote management and control of the building equipment, and improve the energy efficiency and comfort of the building.

Municipal Engineering: In municipal water supply, drainage, gas and other systems, it can be used to monitor and control the operating status of related equipment, such as monitoring the water level, flow rate, pressure and other parameters, and remotely control the opening and closing of valves to achieve the intelligent management of municipal facilities.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|